Deall Mathau Tricone: Dan Wirolog vs. Mewnosodi Carbide Wolframian

Gwahaniaethau Strwythurol a Chymhariaeth Perfformiad

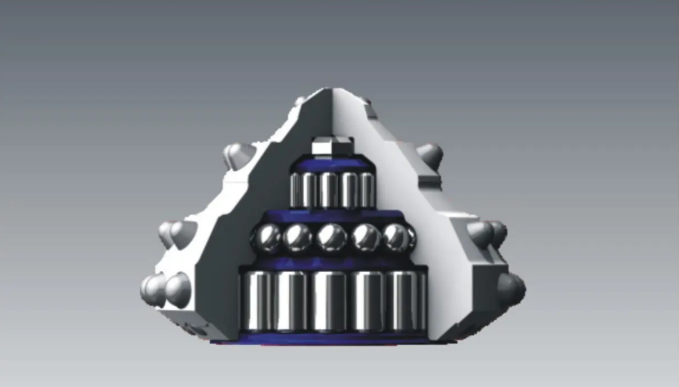

Mae edrych ar y gwahaniaethau strwythurol rhwng dannedd dur a phethau tricone mewnosod carbydd wolfften yn datgelu rhai cyferbyniadau diddorol. Mae gan ddarnau dannedd dur dyluniad llawer symlach o'i gymharu â'r adeiladu cymhleth sydd ei angen ar gyfer mewnosod carbydd tungsten. Mae'r gwahaniaethau strwythurol hyn yn bwysig iawn o ran pa mor dda maen nhw'n bore ac pa mor hir maen nhw'n para. Mae profiad maes yn dangos bod darnau carbydd tungsten yn tueddu i fod yn fwy hir na'r rhai sy'n cael eu gwthio o ddŵr tua tair i bedair gwaith mewn ffurfiadau creig caled yn ôl gwahanol adroddiadau diwydiant. Mae profion ymarferol ar draws gwahanol safleoedd drilio yn dangos yn gyson bod carbydd wolfften yn cadw ei ymyl torri yn llawer gwell yn ystod gweithrediadau hir mewn amodau daearyddol anodd. Ar gyfer cwmnïau olew a nwy sy'n gweithio mewn amgylcheddau heriol, mae hyn yn golygu llai o newidiadau a llai o amser stopio. Mae'r gwrthsefyll gwisgo rhagorol yn gwneud mewnosodiau carbydd tungsten yn werth yr fuddsoddiad er gwaethaf costau cychwynnol uwch, yn enwedig mewn prosiectau lle mae hir oes offer yn effeithio'n uniongyrchol ar ganlyniadau llinell isaf.

Darnau Dant Ddur: Cymwysiadau a Termau

Mewn gwaith geo-dechnoleg, mae darnau dannedd dur wedi ennill tracsion oherwydd eu bod yn torri trwy ddeunydd yn eithaf ymosodol. Maen nhw'n gweithio'n well ar deunyddiau melys fel creig a chrediau lle nad yw'r mynd yn rhy galed. Ar gyfer twylliau dirgel lle nad oes angen i ni fynd yn ddwfn iawn, mae'r darnau hyn yn tueddu i fod yn rhatach nag opsiynau eraill, sy'n eu gwneud yn ddeniadol ar gyfer prosiectau buddsoddiol. Ond mae problemau'n dechrau ymddangos pan fyddwn yn taro'r creigiau caled. Ni all y dannedd ddal yn erbyn granit neu basalt heb gwisgo'n gyflym. Mae unrhyw un sydd wedi profi drilio trwy ddeunyddiau casgwrol yn gwybod pa mor gyflym y mae'r dannedd dur yn cael eu chwyno, gan wneud y gweithrediad cyfan yn llai effeithlon ac yn byrhau'r amser y bydd y darn yn para cyn ei fod angen ei ddisodli. Felly, ie, mae'r ddwynnau dur yn gwneud gwaith gwych mewn rhai sefyllfaoedd, ond nid oes neb yn disgwyl iddynt ymdopi â phob math o ffurfioedd creig sydd yno.

Difrod Mewnosod Carbide Tungsten: Buddion mewn Ffurfannau Galed

Mae'r darnau mewnforio carbydd tungsten yn sefyll allan oherwydd eu bod yn para'n hirach ac yn gwrthsefyll gwisgo'n well na'r rhan fwyaf o ddewisiadau amgen, sy'n esbonio pam eu bod yn gweithio mor dda wrth ddrygio trwy graig caled fel granit a ffurfiadau basalt Y peth sy'n bwysig iawn yma yw sut mae'r darnau hyn yn cynnal yn erbyn pwysau eithafol yn ystod gweithrediadau drilio dwfn lle mae offer safonol yn diflannu. Wrth gwrs, mae'r pris ymlaen llaw ar gyfer mewnosodiau carbydd tungsten yn uwch na'r hyn yr ydym yn ei dalu am ddarnau dannedd dur arferol, ond meddyliwch am hyn: mae'r doleri ychwanegol hynny'n cael eu talu yn ôl sawl gwaith yn ôl diolch i lai o adnewyddau sydd eu hangen a llai o Pan fyddant yn gweithio gyda deunyddiau sy'n torri i ffwrdd ar drwsiau drylli confensiynol, mae gweithwyr yn dod o hyd i'w hun yn dibynnu ar carbydd tungsten am ei berfformiad dibynadwy o ddydd i ddydd. Mae'r ffaith y gall y darnau arbenigol hyn ymdopi â rhai o'r senario'r drilio mwyaf caled yn golygu eu bod yn dod yn offer hanfodol pryd bynnag y mae angen i beirianwyr fyned i mewn yn ddwfn i ffurfiadau daearyddol caled.

Cyfateiddio Math o Bit â Ffurfathiad y Carreg

Dewis Bit ar gyfer Ffurfathiadau Meddal i Gyfrwng

Mae cael y dril iawn yn gwneud y gwahaniaeth i gyd wrth weithio trwy amodau llawr melys i gymedrol. Mae'r ffurfiadau hyn yn amrywio'n eithaf bach mewn gwirionedd yn amrywio o bethau fel haenau creig sedimentary i lawr i gymysgedd graig a tywod. Ar gyfer y math hwn o dir, mae'r rhain yn gweithio'n well oherwydd eu bod yn torri trwy deunyddiau melys yn llawer gwell na dewisiadau eraill. Mae yna sawl peth sy'n werth meddwl amdanyn nhw wrth ddewis ychydig. Mae'n amlwg pa mor gyflym mae'n drilio, ond mae'n bwysig hefyd a all ryddhau'r cnau hynny o'r twll yn effeithlon. Mae peirianwyr maes yn gwybod bod hyn yn effeithio ar sut mae popeth yn rhedeg yn gyffredinol. Bydd y rhan fwyaf o bobl sydd wedi bod yn ymwneud â gweithrediadau drilio ers blynyddoedd yn dweud wrthych bod cyfateb y bit i'r gwaith yn arbed arian yn y tymor hir tra gwneud gweithrediadau yn haws o ddydd i ddydd.

Uwchraddio'r Tricone Bits ar gyfer Cerrig Galed/Abrasive

Mae angen rhai addasiadau arbennig i wneud i ddarnau tricone weithio'n dda mewn ffurfiadau creig caled a chlymu i gynyddu eu perfformiad ar y safle. Mae'r mewnosodwyr carbydd tungsten yn gwneud y gwahaniaeth i dorri trwy ddeunydd caled gan gadw'r darn rhag gwisgo'n rhy gyflym. Mae gweithredwyr drilio'n gwybod bod angen iddynt ddryslynu gyda chyflyrau cylchred a chywiro'r eiddo llwch ar ddiwedd y gweithrediadau i gael canlyniadau da o'u cyfarpar. Bydd y rhan fwyaf o weithwyr profiadol yn dweud wrth unrhyw un sy'n gofyn bod cael y gosodiadau hynny yn iawn yn bwysig iawn i wneud cynnydd mewn sefyllfaoedd graig. Mae yna lawer o gyngor wedi'u profi'n fanwl yn y byd am sut i sicrhau bod y darnau hynny'n para'n hirach ac yn gweithio'n well o dan amodau heriol.

Technegau Asesu Daithwrol

Mae cael y darn tricone cywir yn dibynnu'n fawr ar asesiadau daearyddol priodol. Mae drwrwyr yn dibynnu ar arolygon seismig, edrych ar boeri, a chasglu sampliau creig i ddarganfod pa fath o ffurfiadau y maent yn delio â nhw cyn casglu'r darnau. Pan fydd timau'n mapio nodweddion strwythurol ardal, maent yn cael darlun llawer clir o'r math y bydd gwahanol offer drilio'n perfformio. Mae llawer o brofiadau maes yn dangos pan fydd cwmnïau'n buddsoddi amser mewn asesiadau manwl, maent yn gorffen yn dewis darnau sy'n gweithio'n well i'r gwaith o'r blaen. Mae'r ymdrech ychwanegol hon yn talu mewn arian go iawn a arbedwyd rhag osgoi camgymeriadau costus yn ystod gweithrediadau drilio gwirioneddol.

Dewis Maint y Ddifrif Cywir ar gyfer Eich Dril

Mae dewis diamedr y drylwr cywir yn bwysig iawn wrth ddelio â gwahanol fathau o llifydd fel dŵr, olew a nwy. Mae maint y bît yn dibynnu ar faint o ddyfnder y mae angen i ni fynd a pha fath o amodau'r ddaear y mae disgwyl iddynt yno. Mae prosiectau olew a nwy fel arfer yn gofyn am ddarnau mwy oherwydd bod rhaid iddynt ymdrin â dyfnder llawer mwy ynghyd â'r casgi dur trwchus hynny sy'n amddiffyn y bore. Ond mae ffynnon dŵr yn adrodd stori wahanol. Mae'r rhan fwyaf o bobl yn cadw gyda phethau diameter llai gan nad oes angen cymaint o ddyfnder ar y swyddi hyn ac mae cynnal llif dŵr da trwy pibellau tynnu'n gweithio'n well yn y ymarfer. Mae cadw pethau'n gyson â maint bytai ar draws sawl safle yn gwneud synnwyr hefyd. Nid oes neb eisiau gwastraffu amser neu arian yn atal gweithrediadau yn hanner drilio dim ond oherwydd bod y bit maint anghywir wedi'i ddefnyddio. Mae canllawiau'r diwydiant yn cefnogi hyn yn eithaf cryf mewn gwirionedd. Ydych chi am sicrhau bod popeth yn rhedeg yn rhwydd? Siaradwch â rhywun sy'n gwybod eu pethau am gyffwrdd maint bit i ofynion swydd benodol. Mae profiad maes gwaith yn aml yn dweud mwy i ni na allai unrhyw lyfr ddosbarth erioed.

Mae cael y cydnawsedd rig cywir yn bwysig iawn wrth ddewis darnau ar gyfer gwaith drilio. Pan nad yw rigiau yn cyd-fynd yn dda â'u rhannau, mae popeth yn dod yn gymhleth yn gyflym. Mae'r manylion torc yn rhywbeth sy'n werth rhoi sylw iddo oherwydd eu bod yn dweud wrthym a oes gan y triwff ddigon o bŵer i weithio'n iawn gyda gwahanol fathau o ddarnau. Os oes unrhyw anghytuno rhwng yr hyn y gall y rig ei wneud a'r hyn y mae'r bït ei angen, mae problemau'n dechrau ymddangos yn eithaf gyflym. Rydym wedi gweld achosion lle mae cyfuno anghywir wedi arwain at gynnydd arafach trwy haenau creigiau a darnau'n gwisgo i lawr yn rhy gynnar. Dyna pam mae edrych ar raglenni gan y gwneuthurwyr yn gwneud synnwyr, ynghyd â gwirio canlyniadau byd go iawn o brosiectau tebyg. Nid yw cydnawsedd da yn unig am wneud pethau'n rhedeg yn esmwyth mae'n cadw gweithwyr yn fwy diogel hefyd gan fod setupiau anghytuno'n tueddu i greu sefyllfaoedd peryglus i lawr.

Mae edrych ar sut mae maint y bît yn effeithio ar effeithlonrwydd drilio yn bwysig iawn wrth geisio darganfod faint y bydd rhywbeth yn costio a pha mor hir y bydd yn ei gymryd. Mae maint y bit yn gwneud gwahaniaeth mewn pa mor gyflym mae pethau'n mynd trwy haenau creigiau, sy'n amlwg yn effeithio ar pa mor effeithlon yw gweithrediadau yn gyffredinol. Mae adroddiadau'r diwydiant a phrofiadau drilio gwirioneddol yn dangos yn eithaf clir bod darnau llai yn tueddu i weithio llawer gwell ar fathau o dir melys lle y gallant symud yn gyflymach, tra bod darnau mwy yn dal yn well mewn ffurfiadau creigiau caled heb dorri i lawr mor gyflym Mae yna hefyd pethau am systemau oeri a sut mae hylifiau'n symud o gwmpas sy'n cael eu heffeithio gan faint y bit hefyd. Mae gweithredwyr sy'n cael y pethau hyn yn iawn yn dewis offer sy'n gweithio orau ar gyfer eu sefyllfa, yn arbed arian a amser yn y broses. Mae rhai cwmnïau wedi gweld gwelliannau go iawn drwy newid maint y bitiau yn seiliedig ar ba fath o garreg y maent yn delio â hi mewn unrhyw safle penodol.

Dyfnder Drilio a Gofynion Gwasgedd

Drilio Dwfn: Ffactorau Cynhyrchedd y Bît

Pan ddaw i weithrediadau drilio dwfn, mae'r amser y bydd y bît yn para'n bwysig iawn oherwydd yr holl amodau caled yno. Yr hyn sy'n effeithio ar fywyd y biti yn wir yw beth maen nhw'n ei wneud o, sut maen nhw'n cael eu dylunio, a pha mor dda oedd y broses gynhyrchu. Mae deunyddiau carbide a diemwnt yn sefyll allan gan fod ganddynt y cryfder sydd ei angen i drin yr amgylcheddau tanffonol eithafol hynny. Mae defnyddio bysiau o ansawdd is yn arwain at oedi costus a chynnydd arafach ar brosiectau drilio. Bydd y rhan fwyaf o brolio profiadol yn dweud i unrhyw un a fydd yn gwrando bod darnau carbid yn perfformio'n well pan fydd yn wynebu'r gwres a phwysedd dwys ar ddyfnder mawr. Mae data maes yn parhau i ddangos i ni fod twylliau dyfnach yn golygu cyfraddau gwisgo bitiau cyflymach, a dyna pam mae'r rhan fwyaf o weithredwyr yn rhoi blaenoriaeth i gael bitiau yn cael eu hadeiladu i bara trwy'r amodau heriol hynny.

Meintion Pwysau a Thechnolegau Sêl

Mae cael dealltwriaeth dda o'r graddau pwysau yn bwysig iawn wrth ddewis darnau tricone ar gyfer gwahanol ddyfnder drilio. Os nad oes gan ddarnau ddigon o gyfradd pwysau, maent yn tueddu i dorri i lawr yn gyflymach sy'n brifo perfformiad cyffredinol ac weithiau'n arwain at broblemau difrifol downhole. Mae technoleg seillio wedi dod yn bwysig iawn i gadw darnau'n ddilys yn y pwysau eithafol yr ydym yn eu gweld mewn pwlliau dyfnach. Mae'r rhan fwyaf o borwyr yn gwybod hyn eisoes. Mae profion maes yn cefnogi gwahanol opsiynau seillio, er bod o-ringiau yn dal i gael sgôr uchaf am atal hylifydd rhag mynd i'r lleoedd anghywir. Yn ôl data maes a gasglwyd dros y blynyddoedd diwethaf, mae technoleg seillio newydd fel deunyddiau poligristalyn a'r dyluniadau seillio micro-yn wir yn ymestyn bywyd bit gan ffin eithaf, yn enwedig mewn ffurfiadau caled lle byddai seillio safonol yn rhoi'r ysbryd ar ôl ychydig

Methiadau mewn Amgylchiadau Pwysau Uchel

Mae'r darnau tricon yn aml yn cael trafferth mewn sefyllfaoedd drilio pwysau uchel, gan wynebu problemau fel difrod erosion a methiant strwythurol llawn. Y rhan fwyaf o'r amser, mae'r materion hyn yn dod i lawr i ddewis y math anghywir o ddarn nad oedd wedi'i adeiladu ar gyfer amodau mor galed. Rydym wedi gweld llawer o achosion mewn bywyd go iawn ar draws gwahanol weithrediadau olew a nwy lle nad oedd darnau yn gallu sefyll yn erbyn pwysau eithafol oherwydd nad oedd eu dyluniad yn unol â'r manylion. Wrth edrych ar ffyrdd o atal y math hwn o ddamwain, mae arbenigwyr yn y maes yn argymell yn gyffredinol fynd am ddarnau a adeiladwyd o ddeunyddiau mwy caled a rhai sydd â systemau selio gwell. Mae angen i dimau drilio mewn gwirionedd i fynd i mewn i'r manylion o ba fath o bwysau y maent yn delio â cyn gwneud unrhyw ddewisiadau offer. Mae cael hyn yn iawn yn golygu arferion gwaith mwy diogel a gweithrediadau llawer mwy llym wrth fynd i'r afael â'r prosiectau gwynyn dyfnach heriol hynny.

Uwchraddio Cyflymder Mowldry a Chynllun y Bit

Ystodau RPM ar gyfer Gwahanol Fathau o Bita

Mae gwybod pa ystod RPM sy'n gweithio orau ar gyfer gwahanol ddarnau tricone yn gwneud y gwahaniaeth i gyd i'r math o weithrediad drilio. Mae gan bob math o ddarn ei fan flas o ran cyflymder cylch, sy'n effeithio'n uniongyrchol ar ba mor gyflym y gall dorri trwy graig a chadw canlyniadau torri da. Mae profion maes yn dangos nad yw cadw o fewn y cyflyrau argymhellir hyn yn unig yn cyflymu pethau ond hefyd yn golygu llai o gwisgo ar ddrysau drydedd costus, felly maent yn para am fwy cyn angen eu disodli. Dylai gweithredwyr bob amser wirio'r hyn y mae gweithgynhyrchwyr yn ei argymell ar gyfer gosodiadau RPM oherwydd mae dilyn y manylion hynny yn helpu i gael y gorau o offer tra'n osgoi damweiniau costus i lawr. Mae'r rhan fwyaf o gwmnïau'n seiliedig ar y argymhellion hyn ar flynyddoedd o brofiadau maes go iawn ar draws gwahanol ffurfiannau daearyddol a chyflyrau drilio.

Cone/Bearing Designs for Speed Efficiency

Mae sut mae cwnes a lladradau wedi'u cynllunio mewn darnau tricone yn bwysig iawn i gael effeithlonrwydd cyflymder gwell ohonynt. Mae'r cydrannau eu hunain angen peirianneg ofalus i reoli llif hylif yn iawn, rhywbeth sy'n effeithio ar ba mor dda mae'r dryllio'n gweithio mewn gwirionedd downhole. Mae ffurfiau conus newydd a chyfresiau llestri cryfach yn lleihau'r frys yn ystod y gwaith, gan wneud y system gyfan yn rhedeg yn rhwydd ac yn gyflymach. Mae gwelliannau diweddar yn dylunio'r bit yn cynnwys pethau fel sianel wedi'i ffurfio'n arbennig sy'n caniatáu i hylif oeri symud trwy'n fwy effeithiol, sy'n cadw tymheredd dan reolaeth ac yn ymestyn pa mor hir y bydd y bit yn para cyn ei fod angen ei ddisodli. Mae'r math hwn o ddatblygiadau dylunio yn esbonio pam bod darnau tricone modern yn perfformio llawer gwell nag oedd modelau hen ychydig flynyddoedd yn ôl.

Dyluniad Systemau Hidroddeithio a Chwella

Mae'r ffordd y mae hylifiau'n symud o amgylch darnau tricone yn chwarae rhan fawr yn sut mae eu systemau oeri yn gweithio, gan gadw pethau ar y tymheredd iawn wrth drilio. Pan nad yw'r hylif yn gwneud ei waith yn iawn, mae'r darnau'n tueddu i or-gymryd yn gyflym iawn, sy'n arwain at gamgymeriadau llawer cyn iddynt gwisgo. Mae techneg oeri da yn gwybod lle i anfon y hylifiau hynny fel bod gwres yn cael gwared â'i hun yn gyflymach, gan gadw popeth yn rhedeg yn esmwyth ar tymheredd sefydlog. Mae rhai enghreifftiau byd go iawn yn dangos darnau gyda lleoliadau jet arbennig sy'n targedu mannau poeth yn uniongyrchol. Mae'r holl welliannau hyn yn tynnu sylw at pam bod peirianwyr yn treulio cymaint o amser yn datrys problemau gwres wrth drilio o dan y ddaear, oherwydd mae gwell oeri'n golygu llai o amser stopio a chanlyniadau mwy dibynadwy gan yr offer.

Ffactorau Pwysig Ychwanegol ar gyfer Dewis Tricone

Cydnawsedd Gwynt Drilio

Mae cael y dewis cyfreithiol o hylif drilio yn gwneud y gwahaniaeth i gael y gorau o ddarnau tricone. Mae'r ffordd y mae'r hylifydd hyn yn rhyngweithio â deunyddiau bach yn effeithio ar sut mae popeth yn gweithio'n dda i lawr. Pan fydd yn delio â gwahanol fathau o garreg, mae'r dewis yn bwysig iawn. Mae llwch sy'n seiliedig ar ddŵr yn tueddu i fod yn rhatach ac yn gweithio ar draws gwahanol sefyllfaoedd, ond nid ydynt bob amser yn torri mewn amodau anodd. Mae hylifiau ar sail olew, ar y llaw arall, yn darparu gwell llwbrydru sy'n helpu i amddiffyn darnau tricone rhag gwisgo gormodol yn ystod gweithrediadau drilio caled. Mae profiad maes yn dangos pan fydd gweithredwyr yn cyfateb eu dewisiadau hylif i'r hyn sy'n digwydd mewn gwirionedd o dan y ddaear, maent yn gweld cyfraddau trwyn cyflymach a chyfnod bywyd bytai hirach. Mae dod o hyd i'r man melys lle mae cyllideb yn cwrdd â pherfformiad trwy gydnawsedd hyblyg cyfatebol yn parhau i fod yn hanfodol i unrhyw un sy'n chwilio am optimeiddio eu proses drilio heb dorri'r banc.

Dadansoddi Cost Cyfnod Byw

Pan edrychwch ar gyfanswm cost darnau tricone trwy gydol eu oes, nid yw'n ddigon i ystyried yn syml beth mae'n ei gostio pan fydd yn cael ei brynu. Mae'r arian a wario ar eu cadw'n rhedeg a pha mor dda maen nhw'n perfformio yn ystod gweithrediadau yn chwarae rhan fawr wrth ddarganfod a ydynt yn werth y buddsoddiad. Mae darnau tricone o ansawdd gwell yn tueddu i dalu drostyn nhw eu hunain yn y pen draw oherwydd nad oes angen eu disodli mor aml ac yn borelio'n well trwy ffurfiadau caled. Mae adroddiadau'r diwydiant yn dangos y patrwm hwn dro ar ôl tro ar draws gwahanol safleoedd. Wrth gwrs, gall y darnau premiwm hyn ddod gyda thalciau pris mwy yn y dechrau, ond mae gweithredwyr yn canfod eu bod yn treulio llai o amser yn datrys problemau ac yn delio â phwysau yn ddiweddarach. Yn y pen draw, mae unrhyw un sy'n cymryd amser i asesu'r holl ffactorau hyn yn iawn cyn prynu fel arfer yn gorffen yn arbed arian yn y tymor hir wrth gael gwell canlyniadau o'u gweithrediadau drilio.

Enw Da'r Gynhyrchydd a Chymhwysterion

Pan fyddant yn edrych ar ddarnau tricone, mae'r rhan fwyaf o weithwyr proffesiynol yn gwybod bod gwirio pwy a'u gwnaeth yn bwysig iawn. Mae hanes cwmni fel arfer yn dweud wrthym a ydynt yn poeni am waith da a syniadau newydd, sy'n effeithio ar ba mor ddibynadwy yw eu offer mewn gwirionedd. Mae ardystiadau gan sefydliadau annibynnol yn gweithredu fel tystiolaeth bod y biti'n cwrdd â safonau penodol o ran ansawdd a swyddogaeth, gan roi heddwch meddwl i gwsmeriaid pan fyddant yn gwario arian ar offer. Mae pobl mewnol i'r diwydiant yn nodi'n rheolaidd bod dewis cynhyrchion sydd â thestyniadau priodol gan wneuthurwyr dibynadwy fel arfer yn golygu cael offer sy'n perfformio'n well. I unrhyw un sy'n ddifrifol am weithrediadau drilio, dylid cymryd amser i ymchwilio i hanes y gwneuthurwr a unrhyw gymeradwyaethau swyddogol yn rhan o'r broses brynu.

Cwestiynau Cyffredin

Beth yw triconau?

Mae triconau'n dremioedd troellog a ddefnyddir ar gyfer torthwys ffyrdd carreg, sydd â thair pen trosganol sydd â don, pob un â theith.

Pam ddewis carbide wolfram yn hytrach na dremioedd daearwyr?

Mae carbide wolfram yn cael ei ffafrio am ei barhauswch mewn ffurfiau cryf, tra bod eithafod o ddur yn fwy addas ar gyfer ffurfiau o gynnes i gymedrig.

Sut mae maint y ddifyn yn effeithio ar effeithloni'r drilio?

Mae maint y ddifyn yn dylanwadu ar gyfraddau colledigaeth; mae difynion llai'n cynnig drilio'n gyntaf mewn ffurfiau gynnes tra bod difynion mwy'n sefydlog mewn carregnau cryfach.

Pa ran mae RPM yn chwarae yn y drilio?

Mae lefelau RPM yn dylanwadu'n uniongyrchol ar gyflymder drilio a llwythran y ddifyn; mae cadw RPM o fewn ystodau optimla yn sicrhau perfformiad a hyd oes gwell.

Sut mae cydnawsedd y lwyth drilio'n gallu effeithio ar berfformiad y ddifyn?

Mae priodweddau'r lwyth drilio'n ymgysylltu â deunyddiau'r ddifyn ac yn gallu dylanwadu'n sylweddol ar effeithloni a hyd oes y ddifynion.

Ystadegau

- Deall Mathau Tricone: Dan Wirolog vs. Mewnosodi Carbide Wolframian

- Cyfateiddio Math o Bit â Ffurfathiad y Carreg

- Dewis Maint y Ddifrif Cywir ar gyfer Eich Dril

- Dyfnder Drilio a Gofynion Gwasgedd

- Uwchraddio Cyflymder Mowldry a Chynllun y Bit

- Ffactorau Pwysig Ychwanegol ar gyfer Dewis Tricone

- Cwestiynau Cyffredin