Եռակի սեղանի տեսակների հասկացությունը՝ թուղթ ատամնավոր դեմ վոլֆրամի կարբիդե ներդիր

Կառուցվածքային տարբերություններ և կատարման համեմատում

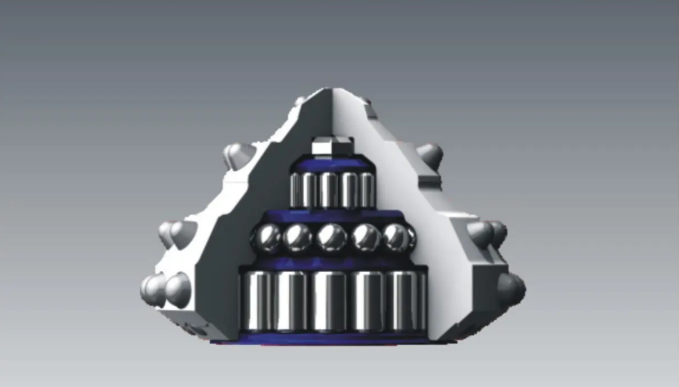

Նայելով պողպատի ատամների եւ վոլֆտրամի կարմրիդի ներմուծման թրիկոնային հատվածների կառուցվածքային տարբերություններին, բացահայտվում են հետաքրքիր հակադրություններ: Սալիկի ատամների հատվածները շատ ավելի պարզ դիզայն ունեն, քան վոլֆտրամյան կարդի տեղադրումների համար անհրաժեշտ բարդ կառուցվածքը: Այս կառուցվածքային տարբերությունները իսկապես կարեւոր են, երբ խոսքը վերաբերում է այն բանի, թե որքան լավ են դրանք փորում եւ որքան ժամանակ են դրանք տեւում: Բացի այդ, փորձը ցույց է տալիս, որ վոլֆտրամի կարդի բիթերը, ըստ տարբեր արդյունաբերական զեկույցների, մոտավորապես 3-4 անգամ ավելի երկար են տեւում, քան պողպատի ատամները կոշտ ժայռային ձեւավորումների մեջ: Տարբեր հորատման վայրերում իրականացված փորձարկումները հետեւողականորեն ցույց են տալիս, որ վոլֆրեմի կարդը շատ ավելի լավ է պահպանում իր կտրող եզրին երկարատեւ գործողությունների ժամանակ ծանր աշխարհաբանական պայմաններում: Նավթային եւ գազային ընկերությունների համար, որոնք աշխատում են դժվար միջավայրերում, դա նշանակում է ավելի քիչ փոփոխություններ եւ ավելի քիչ անջատումներ: Բարձր սպառման դիմադրությունը վոլֆրանի կարդի տեղադրումները արժե ներդրումներ կատարել, չնայած ավելի բարձր սկզբնական ծախսերին, հատկապես այն նախագծերում, որտեղ սարքավորումների երկարատեւությունը ուղղակիորեն ազդում է արդյունքների վրա:

Պողպատե ատամնավոր բիթեր. կիրառում և սահմանափակումներ

Գեոտեխնոլոգիական աշխատանքներում պողպատե ատամների հատվածները մեծ տարածում են գտել, քանի որ դրանք բավական ագրեսիվ կերպով կտրում են նյութը: Նրանք լավագույնս աշխատում են ավելի փափուկ նյութերի վրա, ինչպիսիք են կավը եւ կրիդը, որտեղ շարժումը շատ դժվար չէ: Փափուկ անցքերի համար, որտեղ մենք պետք չէ գնալ շատ խորը, այս հատվածները սովորաբար ավելի էժան են, քան այլ տարբերակները, ինչը նրանց գրավիչ է դարձնում բյուջետային գիտակցված նախագծերի համար: Բայց խնդիրները սկսում են հայտնվել, երբ մենք բախվում ենք ավելի ծանր քարերի հետ: Ատամները չեն կարող դիմակայել գրանիտին կամ բազալտին առանց արագ քայքայվելու: Բոլոր նրանք, ովքեր փորձել են փորել կեղտոտ նյութերի միջով, գիտեն, թե որքան արագ են կծվում պողպատե ատամները, ինչը ամբողջ գործողությունը դարձնում է ավելի անարդյունավետ եւ կարճացնում է այն ժամանակահատվածը, երբ կոտրվածքը պետք է փոխարինվի: Այսպիսով, այո, պողպատե ատամները հիանալի աշխատանք են կատարում որոշ իրավիճակներում, բայց ոչ ոք չի ակնկալում, որ դրանք կկարողանան կառավարել բոլոր տեսակի ժայռերը:

Տունգստենե կարբիդե ներդիրային բիթեր. առավելությունները կարծր կարուցումներում

Վոլգմենային կարդի տեղադրման հատվածները առանձնանում են այն պատճառով, որ դրանք ավելի երկար են տեւում եւ դիմադրում են սպառմանը, քան այլընտրանքները, ինչը բացատրում է, թե ինչու են դրանք այդքան լավ աշխատում, երբ բորբոքում են խիստ ժայռեր, ինչպիսիք են գրանիտը Այստեղ կարեւոր է, թե ինչպես են այս հատակները դիմում ծայրահեղ ճնշմանը խորը փորման գործողությունների ժամանակ, երբ ստանդարտ գործիքները պարզապես կոտրվում են: Իհարկե, վոլֆրանի կարդի տեղադրման համար նախնական գինը ավելի բարձր է, քան սովորական պողպատի ատամների համար վճարելը, բայց մտածեք այս մասին. այդ լրացուցիչ դոլարները շատ անգամ ավելի շատ են վճարվում, շնորհիվ ավելի քիչ փոխարինման եւ մեքենայի անջատման ժամանակի: Երբ աշխատում են սովորական փորիչների վրա մաքրվող նյութերի հետ, գործարարները ամեն օր ապավինում են վոլֆտրամի կարմրի վրա, որպեսզի այն հուսալիորեն աշխատի: Այն փաստը, որ այս մասնագիտացված հատիկները կարող են հաղթահարել ամենադժվար փորման սցենարները նշանակում է, որ դրանք անփոխարինելի սարքավորում են դառնում, երբ ինժեներները պետք է խորը ներթափանցեն դժվար երկրաբանական ձեւավորումների մեջ:

Փորիչ գլխիկի տեսակի համապատասխանեցում ապարի ձևավորմանը

Փորիչ գլխիկի ընտրություն փափուկից մինչև միջին կարծրությամբ շերտերի համար

Ճիշտ փորն ընտրելը կարեւոր է, երբ աշխատում եք մեղմ եւ միջին հողի պայմաններում: Այս ձեւավորումները բավականին տարբեր են, սկսած հյուսվածքային ժայռերի շերտերից մինչեւ ժայռի եւ ավազի խառնուրդներ: Այս տեսակի հողատարածքի համար պողպատից ատամները լավագույնս աշխատում են, քանի որ դրանք շատ ավելի լավ են կտրում ավելի փափուկ նյութը, քան այլ տարբերակները: Սակայն մի քանի բան կա, որոնց մասին արժե մտածել, երբ մի քիչ ընտրում ես: Իհարկե կարեւոր է, թե որքան արագ է նա փորում, բայց նույնքան կարեւոր է, թե արդյոք նա կարող է արդյունավետորեն մաքրել այդ հատումները: Դաշտային ինժեներները գիտեն, որ դա ազդում է ընդհանուր առմամբ ամեն ինչի վրա: Մարդկանց մեծ մասը, ովքեր տարիներ շարունակ փորձել են փորագրման աշխատանքները, կասեն, որ գործի հետ համընկնումը երկարաժամկետ հեռանկարում գումար է խնայում, իսկ գործառույթները օրեցօր ավելի սահուն է դարձնում:

Տրիկոնային պտուտակների օպտիմալացում կոշտ/մաշող ապարների համար

Տրիկոնային հատվածները լավ աշխատելու համար կոշտ, կեղտոտ ժայռերի ձեւավորման մեջ անհրաժեշտ են որոշ հատուկ փոփոխություններ, որպեսզի դրանք բարելավեն իրենց կատարումը: Այդ վոլֆրեմի կարդի տեղադրումները իսկապես տարբերություն են ստեղծում, երբ խոսքը վերաբերում է կոշտ նյութի հատմանը, միաժամանակ պահելով հատվածը շատ արագ սպառվելուց: Բորբոքումների օպերատորները գիտեն, որ պետք է փոխեն պտույտների արագությունը եւ կարգավորեն կեղեւի հատկությունները, որպեսզի իրենց սարքավորումները լավ արդյունքներ ունենան: Շատ փորձառու մասնագետներ կպատմեն, որ ճիշտ տեղադրումը շատ կարեւոր է, որպեսզի առաջընթաց լինի կոշտ իրավիճակներում։ Բազում փորձարկված խորհուրդներ կան, թե ինչպես ապահովել, որ այդ կտորները ավելի երկար մնան եւ ավելի լավ աշխատեն դժվար պայմաններում:

Երկրաբանական գնահատման տեխնիկաներ

Ճիշտ թրիկոնային հատվածը ստանալը մեծապես կախված է ճիշտ երկրաբանական գնահատականներից: Բորբոքումները սովորաբար ապավինում են սեյսմիկ հետազոտություններին, փորումներին եւ քարանձավների նմուշները հավաքելուն, որպեսզի պարզեն, թե ինչ տեսակի ձեւավորումների հետ են զբաղվում նախքան հատվածները վերցնելը: Երբ թիմերը քարտեզագրում են տարածքի կառուցվածքային հատկանիշները, նրանք շատ ավելի պարզ պատկերացում են ստանում, թե որքան լավ է կատարվելու տարբեր հորատման սարքավորումները: Շատ փորձեր ցույց են տալիս, որ երբ ընկերությունները ժամանակ են ծախսում մանրակրկիտ գնահատումների վրա, նրանք ընտրում են այն բիթերը, որոնք շատ ավելի լավ են աշխատում իրենց գործի համար: Այս լրացուցիչ ջանքերը վճարվում են իրական դոլարներով, որոնք խուսափում են թանկ սխալներից իրական փորման գործողությունների ժամանակ:

Ընտրեք ճիշտ բիթի չափը ձեր հորատիչի համար

Ճիշտ ջրազարդի տրամագիծը շատ կարեւոր է, երբ գործ ունենք ջրի, նավթի եւ գազի պես տարբեր տեսակի ջրհորների հետ: Բիթի չափը կախված է նրանից, թե որքան խոր պետք է գնանք եւ ինչպիսի պայմաններ ենք ակնկալում այնտեղ: Նավթի եւ գազի նախագծերը սովորաբար պահանջում են ավելի մեծ հատիկներ, քանի որ դրանք պետք է զբաղվեն շատ ավելի մեծ խորություններով եւ հաստ պողպատե կահույքներով, որոնք պաշտպանում են հորատման անցքը: Ջրի աղբյուրները այլ պատմություն են պատմում: Մարդկանց մեծ մասը մնում է փոքր տրամագծով, քանի որ այս աշխատանքները չեն պահանջում այնքան խորություն, եւ ավելի նեղ խողովակներով ջրի լավ հոսքը պահպանելը ավելի լավ է գործում: Բիթների չափերի համահունչ պահելը բազմաթիվ կայքերում նույնպես իմաստ ունի: Ոչ ոք չի ցանկանում ժամանակ կամ գումար վատնել գործողությունները դադարեցնելու համար, միայն այն պատճառով, որ սխալ չափի բիթ է օգտագործվել: Արդյունաբերության ուղեցույցները բավականին հստակ են հաստատում այս փաստը: Ցանկանում եք համոզվել, որ ամեն ինչ սահուն է ընթանում: Խոսեք մեկի հետ, ով գիտի բիթների չափերի համապատասխանեցման մասին աշխատանքային պահանջներին: Տեղի ունեցած փորձը մեզ հաճախ ավելի շատ է պատմում, քան որեւէ դասագիրք կարող է։

Ճիշտ սարքավորման համակարգի համատեղելիությունը շատ կարեւոր է փորման աշխատանքների համար հատիկներ ընտրելու ժամանակ: Երբ սարքավորումները չեն համընկնում իրենց մասերի հետ, ամեն ինչ արագ բարդանում է: Տոմպի չափանիշները ուշադրության արժանի են, քանի որ դրանք մեզ ասում են, թե արդյոք սարքավորումը բավականաչափ հզորություն ունի տարբեր տեսակի բիթերի հետ ճիշտ աշխատելու համար: Եթե կա որեւէ անհամապատասխանություն այն բանի միջեւ, թե ինչ կարող է անել սարքը եւ ինչ է պետք, խնդիրները սկսում են հայտնվել բավական արագ: Մենք տեսել ենք դեպքեր, երբ սխալ համադրությունները հանգեցրել են ավելի դանդաղ առաջընթացի քարերի շերտերի եւ կտորների միջոցով, որոնք շատ շուտ են սպառվում: Ահա թե ինչու է իմաստը տալիս արտադրողների բնութագրերը դիտել, ինչպես նաեւ իրական արդյունքները ստուգել նմանատիպ նախագծերից: Լավ համատեղելիությունը ոչ միայն հանգեցնում է գործերի անխափան ընթացքին, այլեւ ապահովում է աշխատողների անվտանգությունը, քանի որ անհամատեղելի պայմանները հանգեցնում են վտանգավոր իրավիճակների:

Դիտելով, թե ինչպես է բիթի չափը ազդում փորման արդյունավետության վրա, շատ կարեւոր է, երբ փորձում ենք պարզել, թե ինչ է ինչ-որ բան արժե եւ որքան ժամանակ է դա կպահանջի: Բիթների չափը իսկապես տարբերություն է ստեղծում այն բաների արագության մեջ, որոնք անցնում են ժայռերի շերտերի միջով, ինչը ակնհայտորեն ազդում է ընդհանուր առմամբ գործառնությունների արդյունավետության վրա: Արդյունաբերության զեկույցները եւ իրական փորագրման փորձերը բավականին հստակ ցույց են տալիս, որ փոքրիկ հատիկները շատ ավելի լավ են աշխատում փափուկ հողի տեսակների համար, որտեղ նրանք կարող են ավելի արագ շարժվել, մինչդեռ ավելի մեծ հատիկները ավելի լավ են պահվում ավելի խիստ ժայռային ձեւավորումների մեջ Կա նաեւ սառեցման համակարգերի եւ հեղուկների շարժման մասին բաներ, որոնք ազդում են նաեւ բիթների չափի վրա: Օպերատորները, ովքեր ճիշտ են օգտագործում այս նյութերը, ընտրում են սարքավորումներ, որոնք լավագույնս համապատասխանում են իրենց իրավիճակին, խնայելով ժամանակ եւ գումար: Որոշ ընկերություններ իրական բարելավումներ են տեսել պարզապես փոխելով բիթների չափերը, ըստ այն ժայռի տեսակի, որի հետ նրանք գործ ունեն տվյալ կայքում:

Հորատման խորություն և ճնշման պահանջներ

Խորացված հորատում. Բիթի տևումը որոշող գործոններ

Երբ խոսքը վերաբերում է խորը հորատման աշխատանքներին, թե որքան ժամանակ է տեւում մի հատվածը, շատ կարեւոր է, քանի որ այնտեղ դժվար պայմաններ կան: Այն, ինչ իսկապես ազդում է բիթերի կյանքի վրա, այն է, թե ինչից են դրանք պատրաստված, ինչպես են դրանք նախագծված, եւ որքան լավ է արտադրական գործընթացը: Կարմիրածնային եւ ադամանդային նյութերը առանձնանում են, քանի որ նրանք ունեն այն ուժը, որը անհրաժեշտ է այդ ծայրահեղ ստորգետնյա միջավայրերին դիմակայելու համար: Ավելի ցածր որակի բիթեր օգտագործելը հանգեցնում է թանկ ուշացման եւ դանդաղ առաջընթացի հորատման նախագծերում: Շատ փորձառու փորագործներ կպատմեն, որ կարդի հատվածները ավելի լավ են աշխատում, երբ դիմում են մեծ ջերմության եւ ճնշման մեծ խորություններում: Դաշտային տվյալները ցույց են տալիս, որ ավելի խոր խոռոչները նշանակում են ավելի արագ պղծման մակարդակ, ինչի համար էլ օպերատորների մեծ մասը առաջնահերթություն է տալիս այդ դժվարին պայմաններում պահպանելու համար:

Ճնշման ցուցանիշներ և հերմետիկ տեխնոլոգիաներ

Սպասման չափանիշների լավ իմացությունը շատ կարեւոր է, երբ ընտրում եք թրիկոնային հատիկներ, որոնք հարմար են բորբոքումների խորության համար: Եթե բիթերը չունեն բավարար ճնշման, նրանք հակված են ավելի արագ կոտրել, ինչը վնասում է ընդհանուր կատարումը եւ երբեմն հանգեցնում է լուրջ խնդիրների downhole. Պտուղային տեխնոլոգիան իսկապես կարեւոր է դարձել այն բանի համար, որ կտորները մնան անթերի այն ծայրահեղ ճնշումների դեպքում, որոնք մենք տեսնում ենք ավելի խորը աղբյուրներում: Բորբոքումների մեծ մասը դա արդեն գիտի: Դաշտային փորձարկումները հաստատում են տարբեր փակման տարբերակներ, չնայած O-շղթաները դեռեւս բարձր գնահատականներ են ստանում հեղուկների սխալ տեղերում հայտնվելը կանխելու համար: Վերջին տարիներին հավաքված տվյալների համաձայն, պոլիկրիսթալին նյութերի եւ այդ միկրո-պտուղների նոր պտուղավորման տեխնոլոգիաները իրականում բավականին երկարացնում են պտուղների կյանքը, հատկապես դժվար ձեւավորման մեջ, որտեղ ստանդարտ պտուղները մի քանի քայլ անց պարզապես հանձնվում են:

Բարձր ճնշման միջավայրերում ձախողումներ

Տրիկոնային հատվածները հաճախ պայքարում են բարձր ճնշման հետքերով, խնդիրներ ունեն, ինչպիսիք են էրոզիայի վնասը եւ ամբողջական կառուցվածքային ձախողումը: Հաճախ այդ խնդիրները հանգում են սխալ տեսակի բիթ ընտրելու, որը չի կառուցվել նման ծանր պայմանների համար: Մենք տեսել ենք շատ իրական դեպքեր նավթի եւ գազի տարբեր գործարքների ժամանակ, երբ բիթերը պարզապես չէին կարող դիմակայել ծայրահեղ ճնշումներին, քանի որ դրանց դիզայնը չէր համապատասխանում բնութագրերին: Այսպիսի վնասվածքների կանխման միջոցները փնտրելով՝ բնագավառի մասնագետները խորհուրդ են տալիս ընտրել ավելի ամուր նյութերից պատրաստված եւ ավելի լավ փակման համակարգ ունեցող հատիկներ։ Բորբոքումների թիմերը պետք է շատ մանրամասն իմանան, թե ինչ ճնշման հետ են զբաղվում, նախքան սարքավորումների ընտրությունը: Այս խնդիրը լուծելու համար անհրաժեշտ է կատարել ավելի անվտանգ աշխատանքային գործառույթներ եւ շատ ավելի հեշտ գործառույթներ, երբ լուծվում են դժվարին խորը ջրհորային նախագծերը:

Պտտման արագության և բուրգի նախագծման օպտիմալացում

Շրջանների տիրույթները տարբեր բուրգերի համար

Տարբեր թրիկոնային հատվածների համար լավագույն ռեպլիկացիայի տիրույթը գիտակցելը մեծ տարբերություն է ստեղծում հորատման աշխատանքների կատարման մեջ: Յուրաքանչյուր տեսակի բիթ ունի իր սիրելի կետը պտույտի արագության առումով, որը ուղղակիորեն ազդում է այն արագության վրա, որը կարող է կտրել ժայռը եւ պահպանել լավ հորատման արդյունքները: "Առաջին անգամ, երբ ես փորձարկեցի, որ մետաղադրամները շատ արագ են շարժվում, ես գտա, որ դրանք շատ ավելի արագ են շարժվում, քան նախկինում։ Օպերատորները պետք է միշտ ստուգեն, թե ինչ են առաջարկում արտադրողները RPM- ի կարգավորումների համար, քանի որ այդ բնութագրերը հետեւելով օգնում է առավելագույնս օգտվել սարքավորումներից ՝ խուսափելով թանկ վնասներից: Ընկերությունների մեծ մասը այս առաջարկությունները հիմնվում են տարիների ընթացքում իրական փորձարկումների վրա տարբեր երկրաբանական ձեւավորման եւ հորատման պայմաններում:

Կոնի/Ամրակալի Կառուցումը Արագության Արդյունավետության Համար

Ինչպես են կոններն ու լեռնաշղթաները նախագծված թրիկոնային հատվածներում, իսկապես կարեւոր է դրանցից արագության արդյունավետության բարձրացում: Դրանց բաղադրիչները պետք է խնամված լինեն, որպեսզի ջրի հոսքը ճիշտ կառավարվի, ինչը ազդում է այն բանի վրա, թե ինչպես է փորը իրականում աշխատում: Նոր կոշտանաձեւ եւ ամուր տեղադրված լեռնաշղթաները նվազեցնում են մաշկային բախումները, ինչը ամբողջ համակարգը դարձնում է ավելի սահուն եւ արագ: Վերջերս բիթի նախագծման մեջ կատարված բարելավումները ներառում են հատուկ ձեւավորված ալիքներ, որոնք թույլ են տալիս ավելի արդյունավետորեն սառեցնել հեղուկները, ինչը ջերմաստիճանը վերահսկում է եւ երկարացնում է բիթի տեւողությունը մինչեւ փոխարինման անհրաժեշտությունը: Այսպիսի նորարարական առաջընթացները բացատրում են, թե ինչու են ժամանակակից թրիկոնային կտորները շատ ավելի լավ աշխատում, քան ավելի հին մոդելները մի քանի տարի առաջ:

Հեղուկի դինամիկա և հովացման համակարգերի դիզայն

Թրիկոնային հատակների շուրջ հեղուկների շարժման ձեւը մեծ դեր է խաղում դրանց սառեցման համակարգերի աշխատանքում, դրանք պահելով ճիշտ ջերմաստիճանում փորման ընթացքում: Երբ հեղուկը չի կատարում իր աշխատանքը, բիթերը շատ արագ գերծերմանում են, ինչը հանգեցնում է խափանման, շատ շուտ, նախքան դրանք սպառվելը: Լավ սառեցման տեխնոլոգիան իրականում գիտի, թե որտեղ ուղարկել այդ հեղուկները, որպեսզի ջերմությունը ավելի արագ ազատվի իրենից, ամեն ինչ անխափանորեն աշխատի կայուն ջերմաստիճանում: Իրական աշխարհի որոշ օրինակներ ցույց են տալիս հատուկ ջրային տեղադրումներ ունեցող բիթեր, որոնք ուղղակիորեն թիրախավորում են թեժ կետերը: Այս բոլոր բարելավումները ցույց են տալիս, թե ինչու են ինժեներները այդքան շատ ժամանակ ծախսում ջերմային խնդիրների լուծման վրա, երբ հորատում են ստորգետնյա հորատման ժամանակ, քանի որ ավելի լավ սառեցումը նշանակում է ավելի քիչ անջատման ժամանակ եւ ավելի հուսալի արդյունքներ սարքավորումների կողմից:

Շիթային բիթերի ընտրության համար հավելյալ կարևոր գործոններ

Հորատման հեղուկի համատեղելիությունը

Բորբոքումների հեղուկների ճիշտ ընտրությունը կարեւոր է, երբ խոսքը վերաբերում է թրիկոնային հատվածներից առավելագույնը օգտվելու հարցին: Այս հեղուկների եւ բիթ նյութերի փոխազդեցությունը ազդում է այն բանի վրա, թե ինչ լավ է աշխատում ամեն ինչ ներքեւի հատվածում: Երբ գործ ունենք տարբեր ժայռերի տեսակների հետ, ընտրությունը շատ կարեւոր է: Ջրի վրա հիմնված կեղեւները ավելի էժան են եւ աշխատում են տարբեր իրավիճակներում, բայց դրանք միշտ չէ, որ աշխատում են դժվար պայմաններում: Մյուս կողմից, նավթի վրա հիմնված հեղուկները ապահովում են ավելի լավ յուղեր, որոնք օգնում են պաշտպանել տրիկոնային հատվածները ծանր փորման գործողությունների ժամանակ չափազանց քաշից: Բացի այդ, փորձը ցույց է տալիս, որ երբ օպերատորները իրենց հեղուկների ընտրությունը համընկնում են ստորգետնյա միջավայրում տեղի ունեցող իրադարձությունների հետ, նրանք ավելի արագ ներթափանցում են տեսնում եւ ավելի երկար ժամանակ են ապրում: Գտնել այն հիանալի կետը, որտեղ բյուջեն համապատասխանում է կատարողականին հեղուկների համապատասխանության միջոցով, շարունակում է լինել կարեւոր ցանկացածի համար, ով ցանկանում է օպտիմալացնել իր հորատման գործընթացը առանց բանկը կոտրելու:

Հաշվետվություն կյանքի ցիկլի արժեքների վերաբերյալ

Երբ դիտարկում ենք թրիկոնային կտորների ընդհանուր արժեքը դրանց կյանքի ընթացքում, բավարար չէ պարզապես հաշվի առնել, թե որքան են դրանք արժե գնվելիս: Փողը, որը ծախսվում է դրանց գործառույթը պահպանելու համար եւ որքան լավ են դրանք գործում, մեծ դեր է խաղում որոշելու համար, թե արդյոք դրանք արժե ներդրում: Ավելի լավ որակի թրիկոնային հատվածները, ի վերջո, վճարում են իրենց համար, քանի որ դրանք այնքան հաճախ չեն փոխարինվում եւ ավելի լավ են փորում խիստ ձեւավորումների միջով: Արդյունաբերության զեկույցները ցույց են տալիս այս ձեւը բազմիցս տարբեր կայքերում: Իհարկե, այս պրեմիում բիթերը կարող են սկզբում ավելի մեծ գներով լինել, բայց օպերատորները գտնում են, որ ավելի քիչ ժամանակ են ծախսում խնդիրները լուծելու եւ հետագայում խափանումների հետ զբաղվելու համար: Օրվա վերջում, ով ժամանակ է հատկացնում այս բոլոր գործոնները պատշաճ կերպով գնահատելու համար նախքան գնելը, սովորաբար երկարաժամկետ հեռանկարում գումար է խնայում եւ ավելի լավ արդյունքներ է ստանում իր հորատման աշխատանքներից:

Արտադրողի հեղինակությունը և հավաստագրերը

Երբ նայում են թրիկոնային կտորներին, մասնագետների մեծ մասը գիտի, որ շատ կարեւոր է պարզել, թե ով է դրանք պատրաստել: Ընկերության փորձը սովորաբար ցույց է տալիս, թե արդյոք նրանք հոգ են տանում լավ աշխատանքների եւ նոր գաղափարների մասին, ինչը ազդում է նրանց գործիքների վստահելիության վրա: Անկախ կազմակերպությունների կողմից ստացված հավաստագրերը վկայում են, որ սարքավորումները համապատասխանում են որակի եւ գործառույթի որոշակի չափանիշներին, ինչը հաճախորդներին հանգիստ է տալիս, երբ նրանք գումար են ծախսում սարքավորումների վրա։ Բիզնեսի ոլորտի մասնագետները պարբերաբար նշում են, որ այն արտադրանքները, որոնք ունեն վստահելի արտադրողների կողմից պատշաճ հավաստագրեր, սովորաբար նշանակում են ավելի լավ գործիքներ: Եթե դուք լուրջ եք վերաբերվում փորման աշխատանքներին, ապա պետք է ժամանակ հատկացնեք եւ՛ արտադրողի պատմությունը, եւ՛ պաշտոնական հաստատությունները ուսումնասիրելու համար։

Հաճախ տրամադրվող հարցեր

Ինչ են տրիկոն բիթերը:

Տրիկոն բիթերը պտտվող փորագրիչ բիթեր են, որոնք օգտագործվում են ժայռային ձևավորումների փշրման համար, և ունեն երեք կոնաձև պտտվող գլուխներ, որոնցից յուրաքանչյուրը ատամներով է ապահովված:

Ինչու ընտրել վոլֆրամի կարբիդ պողպատե ատամների փոխարեն:

Տունգստենի կարբիդեի բիթերը նախընտրելի են դրանց տևականության համար կարծր ապարներում, մինչդեռ պողպատե ատամնավոր բիթերը ավելի հարմար են նուրբից մինչև միջին ապարների համար:

Ինչպե՞ս է բիթի չափը ազդում փորման արդյունավետության վրա:

Բիթի չափը ազդում է թափանցման արագության վրա. փոքր բիթերը ավելի արագ են փորում նուրբ ապարներում, իսկ մեծ բիթերը կայուն են կարծր ժայռերում:

Ինչպիսի՞ դեր է կատարում RPM-ը փորման գործում:

RPM-ի մակարդակները ուղղակիորեն ազդում են փորման արագության և բիթի մաշվածության վրա. օպտիմալ RPM-ի պահպանումը ապահովում է ավելի լավ արդյունավետություն և տևականություն:

Ինչպե՞ս կարող է փորման հեղուկի համատեղելիությունը ազդել բիթի արդյունավետության վրա:

Փորման հեղուկի հատկությունները փոխազդում են բիթի նյութերի հետ և կարող են էականորեն ազդել բիթերի արդյունավետության և կյանքի տևողության վրա:

Բովանդակության աղյուսակ

- Եռակի սեղանի տեսակների հասկացությունը՝ թուղթ ատամնավոր դեմ վոլֆրամի կարբիդե ներդիր

- Փորիչ գլխիկի տեսակի համապատասխանեցում ապարի ձևավորմանը

- Ընտրեք ճիշտ բիթի չափը ձեր հորատիչի համար

- Հորատման խորություն և ճնշման պահանջներ

- Պտտման արագության և բուրգի նախագծման օպտիմալացում

- Շիթային բիթերի ընտրության համար հավելյալ կարևոր գործոններ

- Հաճախ տրամադրվող հարցեր