Introductio: Necessitas Rite Curandi Tricones

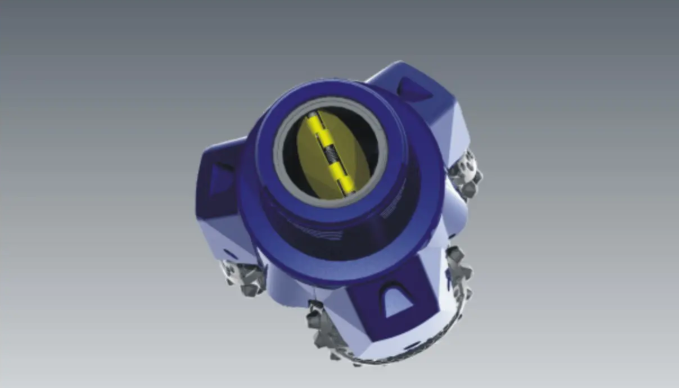

Tergmina triconica munere magno gaudent in operationibus forandi apud varia artes. Cum his instrumentis cura debita adhibetur, melius operantur et diutius durant quam illa quae neglecta sunt tempore. Eae turmae forandorum quae inspectionibus et purgationibus regulariter inserviunt, minus difficultatibus in operatione obnoxi sunt. Sine hac cura, tergmina attrita interrupiones inopinatas medii operis causare possunt, id quod tempus amittitur et pecunia in reparandis vel substituendis emergentibus expenditur. Tergmena bene curata plerumque menses aliquot diutius durant quam neglecta, itaque inspectiones periodicae prodesse possunt cuiquam forandi commercio qui rem quaerit ut conpendia faciat et opera sua impedimentis vacent.

Purgo Regularis: Cur et Quomodo Tu Tricone Bits Post Usum Singulum Purges

Cur Purgo Est Necessaria Pro Tricone Bit Longevitate

Tergere regulariter tribrachas rotantes vere facit differentiam in duratione eorum. Cum sordes et minerales coepissent accumulari intra bracham, incidunt in id quomodo bene secent formaciones petrosas. Tribrachae quae post singulos usus purgantur solent acumen conservare diutius. Data eorum quae in industria sunt demonstrant tribrachas cura accepta solere manere functionales circiter 30 percent longius quam illae sordidae relictae in custodia. Huiusmodi curatio proficit multis modis. Primum quidem, operatoribus minus pecuniae expendunt in locanda instrumenta vetusta. Praeterea, tribrachae purgatae melius operantur dum actuaria forantia quia omnia secentur leviorem sine tota illa sordium massa impediente.

Processus Purificationis Gradatim Pro Optima Performance

Tricone bit curare comprehendit processum purificationis post singulum usum, ut efficeienter operentur. Simplex tamen exacta consuetudo magnopere in generalem performantiam et longevitatem bitum influere potest:

- Rinsatio : Incipe per bitum cum aqua enixam ad detergenda sordida et particulas quae durante usum colligi potuerunt. Hoc iuvat ut vetustas effugatur satis.

- Fregere : Utere harundine tenera et detergente miti ad bitum diligenter fregere. Adhibe speciatim curam ad rimas ubi sordes latere solent. Hoc gradus certe omnes reliquias pertinaces tolli satis.

- Ultima Enixio : Bitum iterum enixa cum aqua pura, omnia detergentia remota. Hoc prohibet ne reliquiae chemicas corrosionem aut damnum causent.

- Ariditas et Lubricatio : Bitum penitus arefacere ne ruginas formet. Post arefactionem, adhibe lubricum tenue ad protegendum bitum et ut in condicione optima maneat usque ad proximum usum.

His purgandi rationibus adhibitae, tria coniuncta rostrata diuturne in summa valetudine manere possunt, ministeriumque firmum et efficax in foraminum operationibus praebendo. Purgatio frequens non solum de performance retinenda agit, sed de pecuniae ratione optime utendo quaestione.

Inspectionis propter Usum et Lacerationem: Primo Signa Damni Invenire

Tripartita rostrata saepe inspicientes vitam eorum iamdudum producere atque in summo actu pergere possumus, dum vitia ante quam nimis gravis fiant deprehendimus. Cum curatores tempore congruo inspectionibus insistant, id quod in duris formis forandis eos tam bene fungatur conservare iuvat. Qualem vero cladum tempore eveniat, et qua arte quaerenda sint quae primo aspectu non patent, scire debemus. Denique hi sectores instrumenti in omni gravi forandi operatione sunt admodum necessarii, igitur eos curare multis in rebus utilitatem afferet.

Signa Usitata Lacerationis in Triconibus

Tricones signa quaedam praebent quae usum et lacerationem indicant, de quibus utentes esse sollicitos debent, ut curatio cito fiant. Haec sunt signa maxime nota:

- Chipped vel Rupti Rotarii : Haec sunt indicia compromissae facultatis secandi, quae suggerunt statim curam esse necessariam. Perioculae regulares vitare possunt aggravationem damni.

- Obtusitas sive Edges Obtusi : Nimia usus saepe ducit ad haec mala, quae acuendam vel substituendam rem necessariam reddunt ad efficienciam forandi retinendam.

- Signa Discolorationis : Discoloratio significat nimium calorem, qui ex lubricatione infirma vel velocitatibus forandis nimis altis oriri potest. Cura diligentia horum factorum damnum ulterius averti potest.

Quomodo Inspectionem Plenam Facere

Inspectiones methodicae vitam et efficienciam rotorum triconum significanter producere possunt:

- Examinatio Superficialis : Incipe per diligentem inspiciendam superficiem roti quaerens rimas visibiles sive loca signa usus ostendentia.

- Analysis Particularis : Adhibe lupa sive instrumenta inspectionis digitalia ad diligentem examinationem dentium rotatorum, qui pro performance optima sunt necessarii.

- Controlla Rerum Sphaericiarum : Examina sphaericias pro ludo et functione ut vitetur rupura rotulae. Exacta operatio sphaericiarum fluxum operationum conservat.

- Documenta : Consuetudine annotare tua inventa ut sequatur conditio fræni temporis. Hoc iuvat in constituendo idoneo ratione proserendi curam ut prosit efficaciter.

Si diligentissime monitores rotulas triconicas pro his signis et peragras inspectiones plenas, utentes possunt perficientiam forandi augere, tempus intermissionis minuere, atque instrumenti diuturnitatem extendere. Examinatio et conservatio regularis ad meliorem frugifitiam et productivitatem operativam efficit.

Lubricatio: Quomodo Lubricare Rotulas Triconicas Recte Ad Operationem Levis Faciendam

Eligere Lubricantem Rectum pro Rotulis Triconicis

Lubricatione idonea optime conducit cum operaris tricone frænos. Cum eligeres lubrica, quaere ea quæ fiant ad tolerandam calorem et pressionem quæ in foramine eveniunt. Conveniantia etiam refert quia quædam materia non bene iunguntur, quod ad collapsus ducit. Electio recta hic perficient operam et amplificat vitam fræni per minorem frictionis damnum. Plures operatori foraminis hoc iam sciunt - lubricatio bona inter primas rationes remanet ne inopinatum calorem subsistat et operationes interrumpat.

Meliora Consilia pro Lubricatione Efficaci

Ut diuturnitatem et efficientiam rotarum triconium conserventur, consilia lubricationis idonea semper sunt sequenda:

- Applicatio Copiosa: Antequam cuspis conseruetur et ante unumquemque usum, copiosam quantitatem lubrificii admove ad omnia partes motiles. Hoc uetat ruginem et cuspis parat ad statim et lenem operationem.

- Contiones Regulares et Refectio: Dum operatio forandi procedit, lubrificium crebro inspice et reple. Hoc usum optimum seruat et uetat ne cuspis constringatur ob deficiens lubrificium.

- Lubrificii Abusum Vitare: Quamuis plura lubrificia adhibere utile uideatur, nimium lubrificii puluerem attrahit, qui uelocius attritum promouet quam minuit. Aequilibrium serua ut cuspis munda et utilis maneat.

His rationibus adhaerendo, cuspides tricones ad summae auctoritatis efficaciam operari sanguine certas, tempus intermissionis et expensas curae minuendo dum aetate instrumenti extenditur.

Recta Condicio: Cuspidum Triconium Condicio Ad Uetendum Corrosionem et Laesionem

Munus magnum habet conservatio tribrachidarum in earum operatione diuturna sine damno environmentali. Invenimus instrumenta in locis siccis ubi temperatio constans manet conservare iuvare ut humiditas non augeatur, quod saepe ferruginem et corrosionem inducit tempore. Ars utilis quae ab operariorum multitudine adhibetur est saccus silicagel in recipientibus conservationis locare aut desiccantia adiicere ut humiditas exsuperans absorbeatur. Hoc simplici passu munitur ut diuturnitas usus tribrachidarum ante refectionem creverit. Bene conservatis tribrachidariis, acuti et operativi semper manent, ut rursus in operibus perforandi statim uti possint.

Cum tribrachia rite ordinantur, operarii celeriter reperiunt quae eis opus sunt, et diutius servare possunt pretiosa instrumenta in meliore forma. Prima aetate est clare notare cistae in quibus reposita sunt, ut omnes sciant ubicumque magnitudines et genera diversa collocari debeant. Tribrachia erigere, non iacere plana, iuvat ea custodire ne abradantur aut confringantur in asperis anfractibus. Rationem habere simplicem inveniendi numerum omnium instrumentorum curat ne quid inter labores amissum sit aut cum aliis rebus confusum. Haec omnia minuta forsitan videntur, sed diuturna utilitate prodesse possunt, tum ad efficientiam processus, tum ad prolongandam usum tribrachiorum ante reponenda.

Renovatio et Reparatio: Quando et Quomodo Renovare aut Reparare Ferramenta Tricone

Iudicando Quando Renovatio Necessaria Sit

Tricone bits requirunt curam regularem ut optime fungantur. Cum operatoribus incipit animadvertere decrementum in eorum capacitate recidendi per formaciones petrosas, hoc saepe significat tempus esse eas mittere ad acuendam. Plurimi in arte dicunt decrescere circa 15-20% in potentia recidendi, comparatum cum novis bitis, esse punctum ubi iterum acuere necessarium est. Per observationem huiusmodi mutationum in efficientia, foratores possunt constituere tempus conservationis antequam difficultates in loco manifeste emergant. Haec ratio anticipativa non solum operationes commode peragere permittit sed etiam vitam equipmenti forandi pretiosi notabiliter prolongat.

Emendatio Professio vs. Sua Curatio Consilia

Dubitamus an tricone bits emendare debemus ipsi an ad profesionalem deferre, quod pecuniam et emendationis successum afficit. Quamquam ipsi acuere rem priorem pecuniam servat, plerique iudicant profesionales meliores resultatus reddere, quod sciunt quae corrigenda sint. Antequam emendationem aggrediamur, fabbricatoris dicta de custodia videre convenit. Suae commentarii saepe indicant quando opus sit adhibere peritum. Horum praecipuorum lectione cognoscimus, utrum negotium sit simplex quod nos tractare possumus an expers scientiae opus sit. Prudentia in iis quae sequimur custodit pretiosas terebras et vitat inutiliter repetitas emendationes.

Cave ne Defectus Ustensilii Appareat: Causae Praecipuae Quibus Caveas

Signa Gravis Appropinquantis Tricone Ustensilii Defectus

Signorum praecocium triconii dentis defectus agnoscere potest vitare maiores molestias futuras. Cum foratione concussiones extrinseci sentiuntur, hoc saepe aliquid esse indicat quod tum cum directione tum cum dente ipso laeso afficitur. Si concussiones ignoratae relinquuntur, eae rem per tempus deteriorem reddunt, quae tandem in operationibus efficaciam minuit. Aliud indicium est nimius calor, qui durante operatione colligitur. Operarii signa supercaloris sentire possunt, cum dentes plus laboris quam solent ad materiam penetrando impendere videntur aut celerius quam ante attriti sunt. Caloris difficultates saepe significare solent dentem iam prope substitutionem esse necessitaturum. Ad haec signa attendere antequam calamitas eveniat, omnem differentiam facit ad operationes sine inopinato tempore interrumpendis continendas.

Cautelae ad Evitandum Molem Catastrophicam

Cautelis praeventivis usurpatis, periculum magnae dentis triconii damni minuitur.

- Examinatio regularis necessaria est – assidua dentium conditio custodiri debet, ut signa attritionis cito agnosci queant et emendationes consequenter plane fiant.

- Cum primum signa frictionis observentur, parametri forationis, ut pressio terebralis et velocitas rotatoria, ita adiiciantur ut laborem terebrae minuant et damnum ulterius diminuant.

- Technologia etiam munere importuno fungitur ad integritatem terebrae servandam. Adhibendo solutiones programmaticas ad praevisionem conservationis, facultates observandi augentur. Haec systemata problemata incipientia monere possunt priusquam convalescant, permittendo actiones correctivas.

His rebus in strategiam conservationis regulariter integratis, duratio vitae terebrarum triconicarum notabiliter augeri potest et efficacia forationis meliorari.

Saepe Interrogata Quaestiones

Quo rei sunt bitae triconicae?

Terebrae triconicae in industria forandi ad secandas formaturas lapideosas duras adhibentur. Saepius in forandis puteis olei, gasi, et aquae utuntur.

Quam saepe conservationem in terebris triconicis meis perficere debeo?

Conservatio regulariter perficienda est, optime post unumquemque usum. Purificatio, inspectio, et lubricatio regularis ad functionem optimam sunt necessariae.

Quae sunt signa quae monent meum triconem acuendum esse?

Si decrementum in efficentia secandi observaveris et ferramentum circa 15% ad 20% suae originalis capacitis amiserit, tempus est iterum acuendi.

Lubricare possumne ego ipse tricones?

Ita, lubricare potes tricones ipse. Cura ut lubricans idoneus typi utaris et eum copiose ad omnia membra motu applices ut optimi resultati fias.

Index Rerum

- Introductio: Necessitas Rite Curandi Tricones

- Purgo Regularis: Cur et Quomodo Tu Tricone Bits Post Usum Singulum Purges

- Inspectionis propter Usum et Lacerationem: Primo Signa Damni Invenire

- Lubricatio: Quomodo Lubricare Rotulas Triconicas Recte Ad Operationem Levis Faciendam

- Recta Condicio: Cuspidum Triconium Condicio Ad Uetendum Corrosionem et Laesionem

- Renovatio et Reparatio: Quando et Quomodo Renovare aut Reparare Ferramenta Tricone

- Cave ne Defectus Ustensilii Appareat: Causae Praecipuae Quibus Caveas

- Saepe Interrogata Quaestiones