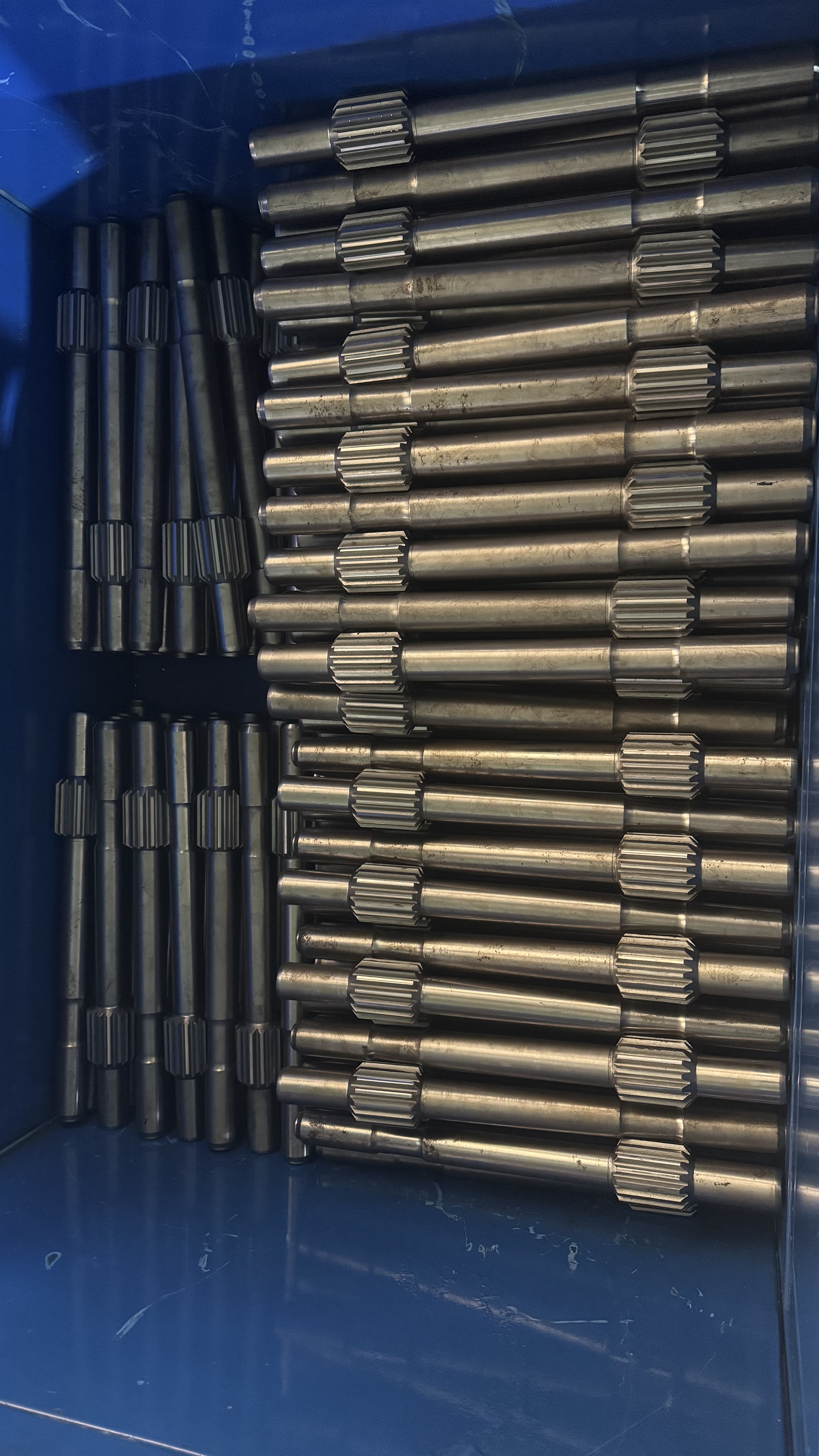

dth hammer assembly

The DTH hammer assembly represents a crucial advancement in drilling technology, serving as an essential component in various drilling operations. This sophisticated system combines a hammer mechanism with a drill bit, operating through compressed air to deliver powerful percussion blows directly to the rock face. The assembly consists of several key components including the back head, check valve, inner cylinder, piston, bit retention system, and drill bit. Working in harmony, these elements create a highly efficient drilling mechanism that converts pneumatic energy into mechanical force. The compressed air not only drives the piston's reciprocating motion but also serves to flush debris from the hole, maintaining optimal drilling efficiency. The DTH hammer assembly excels in applications requiring deep hole drilling, particularly in hard rock formations where conventional drilling methods may prove ineffective. Its versatility makes it invaluable in mining operations, water well drilling, construction projects, and geological exploration. The system's design ensures consistent performance at various depths, maintaining drilling accuracy and speed even in challenging conditions. Modern DTH hammer assemblies incorporate advanced materials and engineering principles to maximize durability and minimize maintenance requirements, resulting in extended service life and reduced operational costs.