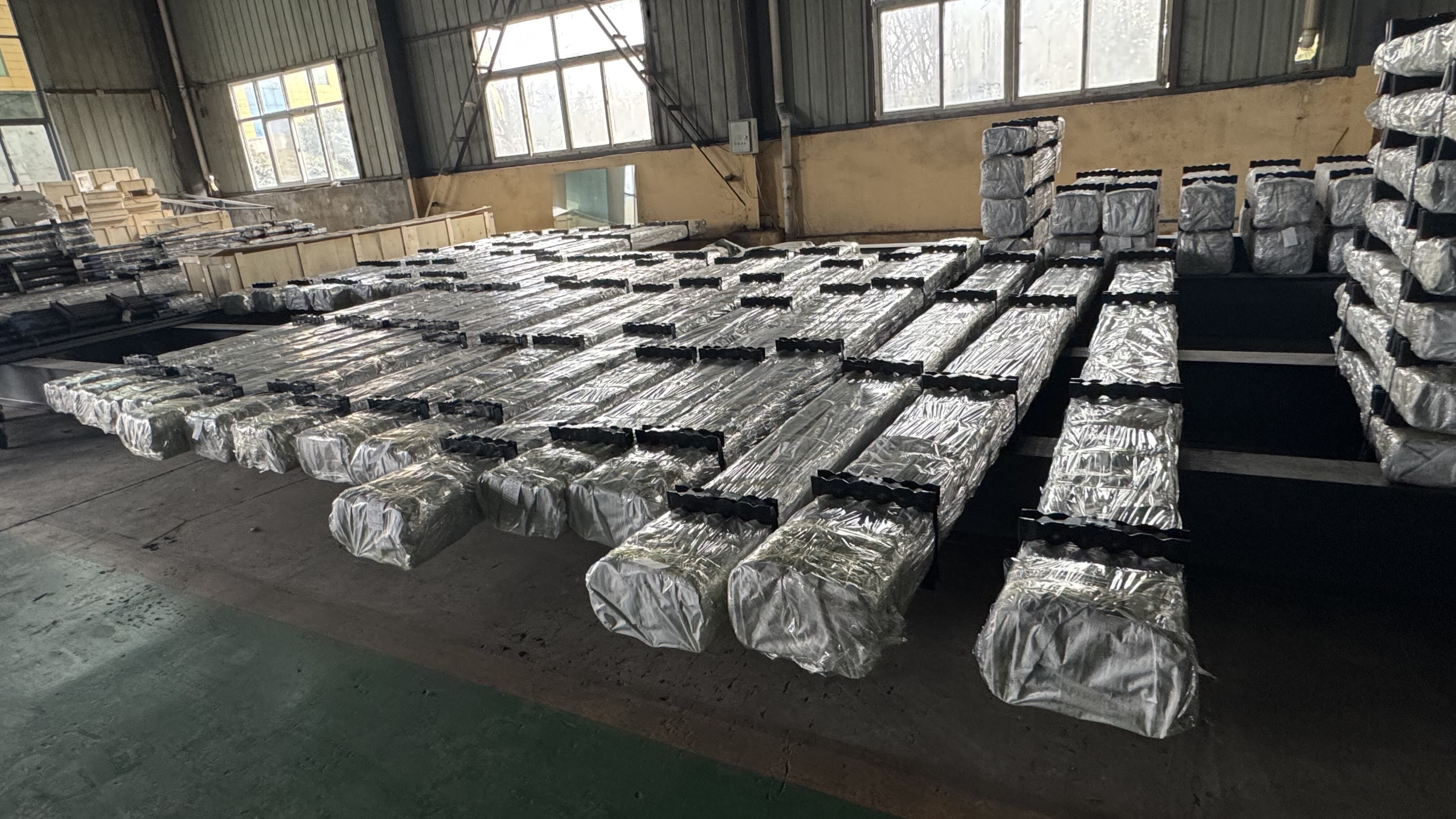

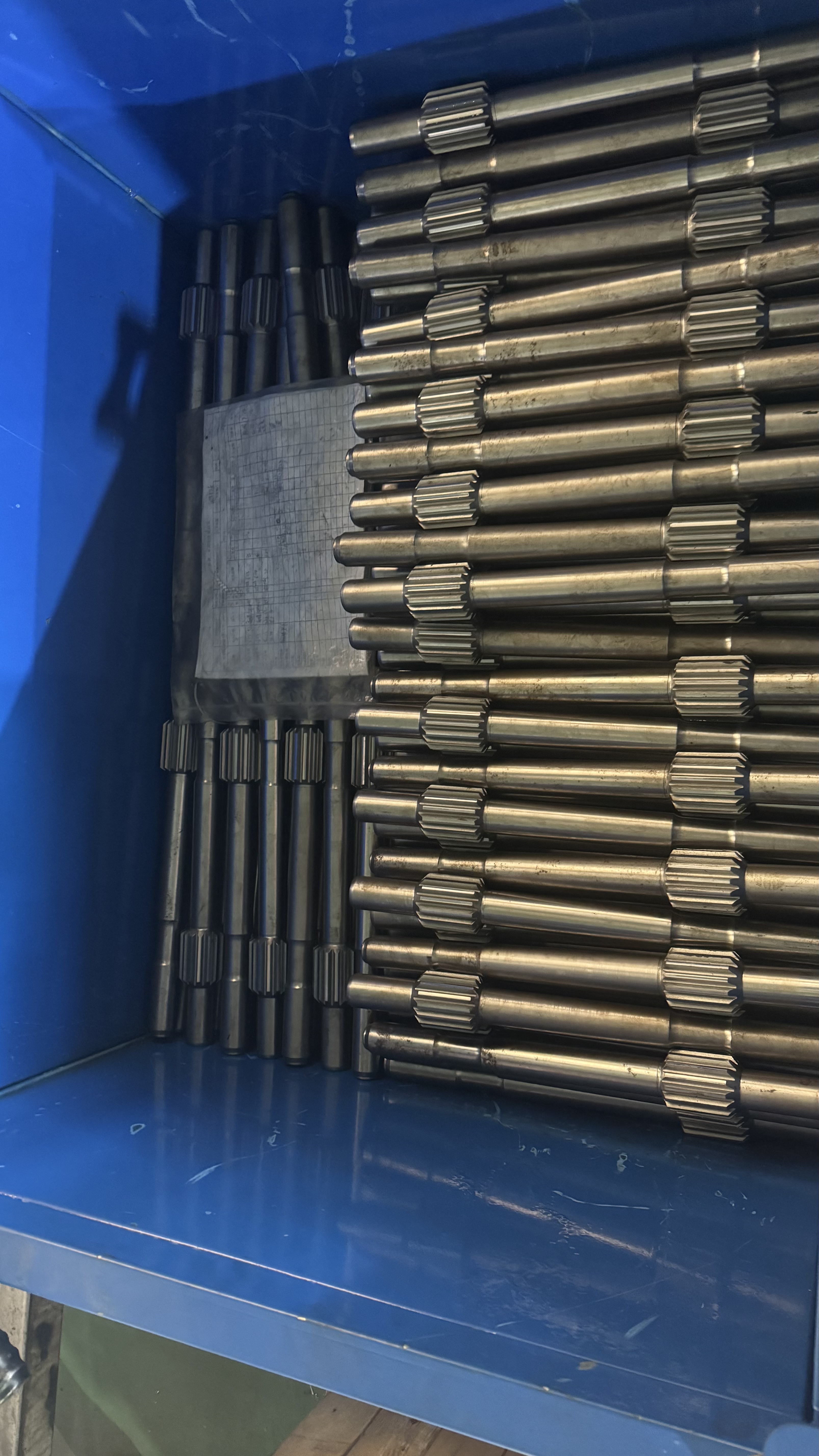

reaming cone opener

The reaming cone opener represents a significant advancement in industrial drilling and machining technology. This precision tool is designed to efficiently enlarge and finish pre-existing holes with exceptional accuracy and surface quality. Operating through a unique conical design, the reaming cone opener combines the functionality of both reaming and hole-opening operations into a single, versatile tool. The device features specially engineered cutting edges arranged in a helical pattern along its conical surface, enabling smooth material removal while maintaining precise dimensional control. Its robust construction, typically crafted from high-grade tool steel with specialized coatings, ensures extended tool life and consistent performance across various materials. The reaming cone opener excels in applications requiring both hole enlargement and surface finishing, making it particularly valuable in automotive manufacturing, aerospace components, and precision engineering sectors. The tool's design allows for superior chip evacuation and coolant delivery, preventing common issues such as chip packing and ensuring optimal cutting conditions throughout the operation. This innovative tool has revolutionized hole-finishing processes by reducing the number of required operations, thereby increasing productivity while maintaining exceptional quality standards.