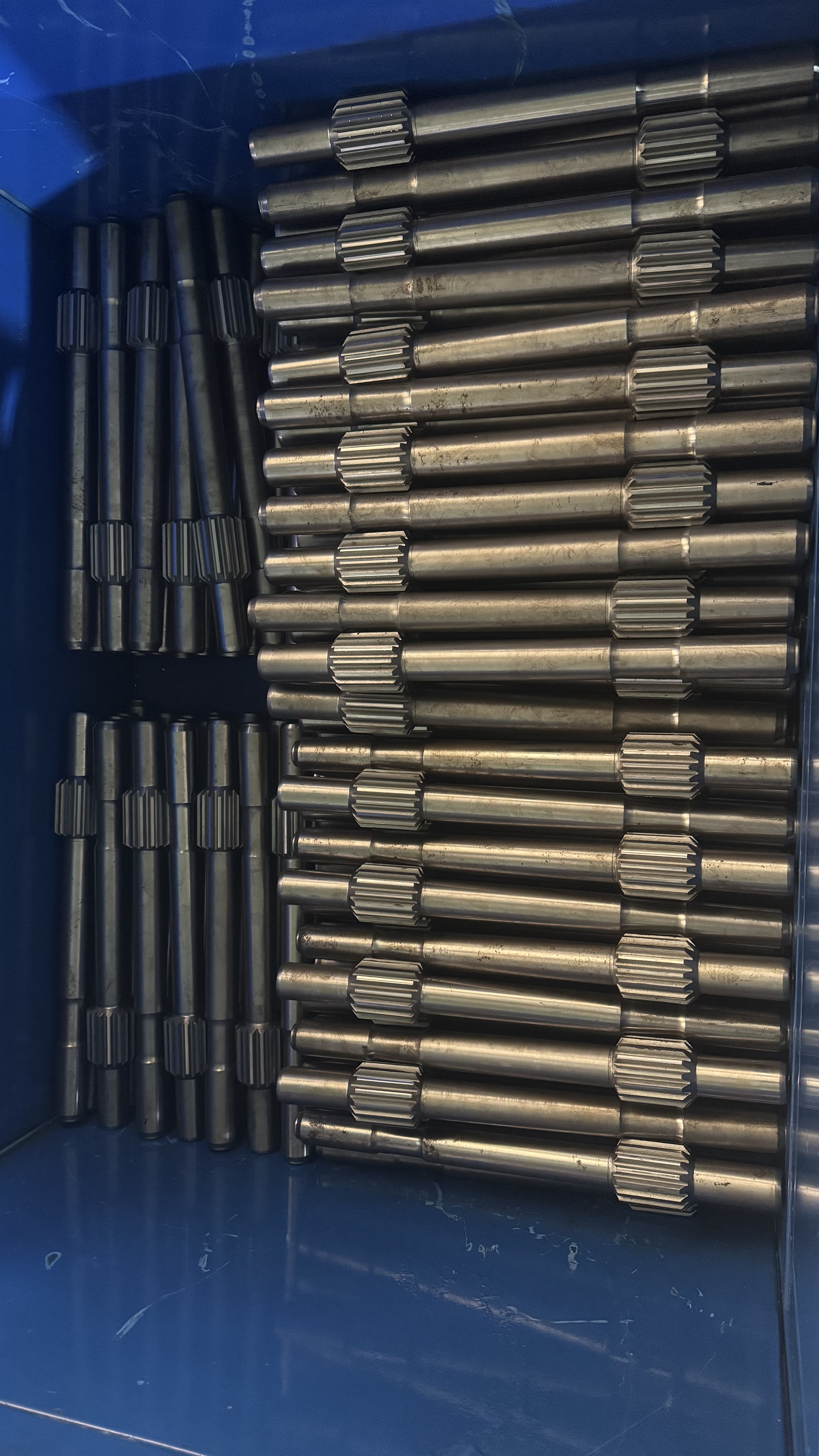

t45 retract button bit

The T45 retract button bit represents a significant advancement in drilling technology, combining durability with user-friendly operation. This innovative tool features a specialized retraction mechanism that allows for quick and efficient bit changes through a simple button press, eliminating the need for additional tools or complicated procedures. The bit is constructed from high-grade steel, ensuring exceptional wear resistance and longevity in demanding applications. Its unique design incorporates a precision-engineered locking system that maintains secure bit retention during operation while allowing for swift releases when needed. The T45 thread pattern ensures compatibility with standard drilling equipment, making it versatile across various applications. The button-activated retraction system features a spring-loaded mechanism that protects against accidental releases, enhancing safety during operation. This bit excels in both surface and underground drilling operations, particularly in mining, construction, and geological exploration projects. The ergonomic design of the retraction button reduces operator fatigue during extended use, while the optimized thread geometry ensures efficient power transfer and reduced wear on threading.