Understanding Down-the-Hole Drilling Challenges

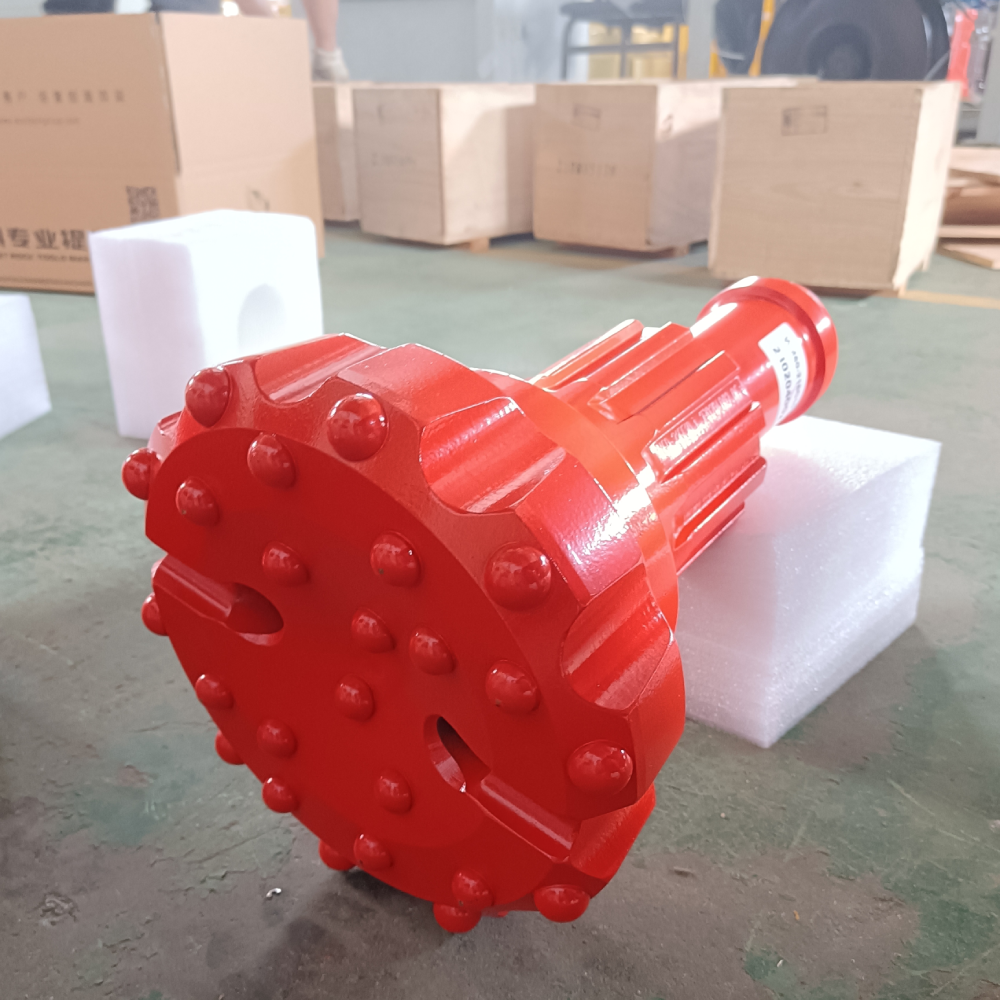

Down-the-hole (DTH) drilling operations present unique challenges that can significantly impact productivity and equipment longevity. At the heart of these operations lies the dth hammer bit, a crucial component that often encounters various issues during drilling processes. Understanding these challenges and implementing effective solutions is essential for maintaining optimal drilling performance and reducing costly downtime.

The complexity of modern drilling operations demands a thorough understanding of dth hammer bit functionality and common problems that arise during use. Whether you're working in mining, construction, or water well drilling, these issues can affect your project's timeline and budget. Let's explore the most prevalent problems and their practical solutions to help you maximize drilling efficiency.

Excessive Bit Wear and Deterioration

Identifying Wear Patterns

The wear patterns on a dth hammer bit can reveal crucial information about drilling conditions and operational issues. Uniform wear across all buttons typically indicates proper drilling practices, while uneven wear patterns may signal underlying problems. Regular inspection of the bit face, gauge buttons, and flushing channels helps detect early signs of deterioration.

Monitoring the rate of wear is essential for predictive maintenance. Experienced operators know that accelerated wear might indicate incorrect operating parameters or challenging ground conditions. Documentation of wear patterns and regular measurements of button protrusion can help establish baseline data for future reference.

Preventive Measures and Solutions

Implementing proper preventive measures can significantly extend the life of your dth hammer bit. Start by ensuring correct rotation speed and feed force settings for the specific ground conditions. The right balance between these parameters helps maintain optimal button impact and reduces unnecessary wear.

Regular maintenance procedures should include proper bit cleaning and lubrication. Remove built-up debris after each shift and inspect for any signs of excessive wear or damage. Using high-quality bit grease and maintaining proper flushing helps prevent premature wear and ensures efficient drilling operations.

Button Breakage and Loss

Common Causes of Button Failure

Button breakage often occurs due to excessive impact force or improper drilling parameters. When the dth hammer bit encounters extremely hard or fractured ground conditions, the buttons may experience stress beyond their design limits. Additionally, insufficient rotation speed can cause buttons to impact the same spot repeatedly, leading to premature failure.

Temperature fluctuations during drilling can also contribute to button problems. Inadequate flushing may cause buttons to overheat, potentially compromising their structural integrity. Understanding these factors helps in developing effective prevention strategies.

Optimizing Button Performance

To maximize button life and prevent breakage, maintain appropriate feed pressure and rotation speed ratios. Regular monitoring of drilling parameters ensures optimal button impact and prevents excessive stress on individual buttons. Consider using specialized button designs for specific ground conditions.

Implement a systematic approach to button maintenance, including regular inspection and regrinding when necessary. Proper grinding techniques help maintain button shape and protrusion, essential for efficient drilling and extended bit life.

Flushing System Complications

Identifying Flushing Issues

Effective flushing is crucial for dth hammer bit performance. Poor chip removal and inadequate cooling can lead to reduced penetration rates and increased wear. Common indicators of flushing problems include reduced penetration speed, excessive dust, and unusual noise during operation.

Regular inspection of flushing channels and ports helps identify potential blockages or wear. Understanding the relationship between air pressure, volume, and drilling effectiveness enables operators to maintain optimal flushing conditions.

Maintaining Proper Flushing

Establish a regular maintenance schedule for cleaning and inspecting flushing channels. Use appropriate tools to remove compacted debris and ensure unrestricted airflow. Monitor air pressure and volume to maintain efficient flushing throughout drilling operations.

Consider using specialized flushing additives when drilling in challenging conditions. These products can help improve chip removal and reduce dust while protecting the dth hammer bit from excessive wear.

Impact Mechanism Failures

Recognizing Impact Issues

The impact mechanism is fundamental to dth hammer bit operation. Signs of impact-related problems include irregular drilling patterns, reduced penetration rates, and unusual vibration. Early detection of these issues prevents more severe damage and reduces downtime.

Regular monitoring of drilling parameters helps identify potential impact mechanism problems. Changes in penetration rate or unusual noise patterns often indicate developing issues that require attention.

Maintaining Impact Performance

Proper maintenance of the impact mechanism includes regular inspection of all components and timely replacement of worn parts. Ensure correct air pressure and lubrication to maintain optimal impact energy transfer.

Training operators to recognize early warning signs of impact mechanism problems helps prevent catastrophic failures. Implement a preventive maintenance schedule based on operating hours and drilling conditions.

Frequently Asked Questions

How often should a DTH hammer bit be inspected?

A comprehensive inspection of your dth hammer bit should be performed at least once per shift, with more frequent checks in challenging ground conditions. This includes examining button condition, flushing channels, and overall bit wear patterns. Document any findings to track wear progression and plan maintenance accordingly.

What causes premature dth hammer bit failure?

Premature failure typically results from a combination of factors including incorrect operating parameters, inadequate maintenance, poor flushing, and challenging ground conditions. Regular monitoring of drilling parameters, proper maintenance procedures, and appropriate bit selection for specific applications help prevent early failure.

How can drilling efficiency be maximized with a DTH hammer bit?

To maximize drilling efficiency, maintain optimal rotation speed and feed pressure for your specific ground conditions. Ensure proper flushing and lubrication, regularly inspect and maintain the bit, and train operators on correct drilling techniques. Monitor drilling parameters continuously and adjust as needed to maintain peak performance.