Maximizing Drilling Performance with Advanced Down-the-Hole Technology

The success of any rock drilling operation heavily depends on selecting the right equipment, and at the heart of this decision lies the choice of a dth hammer bit. These specialized tools have revolutionized the drilling industry by offering unprecedented levels of efficiency and precision in challenging geological conditions. Understanding the nuances of dth hammer bit selection can mean the difference between project success and costly setbacks.

Modern drilling operations across mining, construction, and exploration sectors rely on these sophisticated tools to penetrate the toughest rock formations. The technology behind dth hammer bit design has evolved significantly, incorporating advanced materials and innovative engineering solutions to meet increasingly demanding project requirements.

Essential Components of DTH Hammer Bits

Button Configuration and Pattern Design

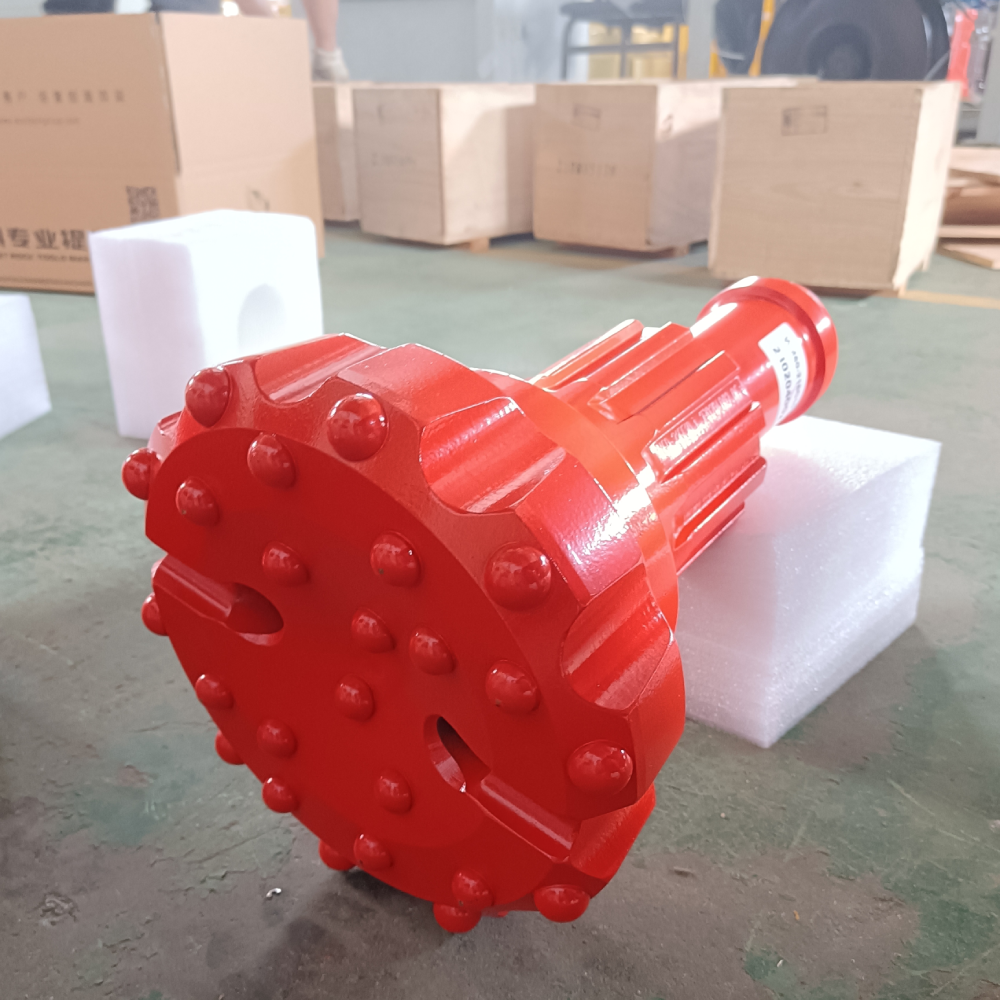

The arrangement of carbide buttons on a dth hammer bit plays a crucial role in its performance. Gauge buttons positioned along the outer diameter maintain hole size, while face buttons handle the primary crushing action. The specific pattern design influences penetration rate, bit stability, and overall drilling efficiency.

Modern bits feature optimized button layouts that balance aggressive cutting action with wear resistance. The spacing between buttons must be carefully calculated to prevent tracking and ensure efficient rock fragmentation. Premium dth hammer bit designs incorporate computational modeling to determine ideal button placement for specific rock conditions.

Material Composition and Durability Features

High-grade carbide compositions form the foundation of quality dth hammer bit construction. The matrix material supporting the buttons must withstand extreme impact forces while providing adequate button retention. Advanced metallurgical processes ensure optimal hardness combinations between the carbide inserts and steel body.

Manufacturers now employ specialized heat treatment processes and surface hardening techniques to enhance wear resistance. The incorporation of premium steel alloys in the bit body extends service life while maintaining structural integrity under high-stress conditions.

Matching Bit Specifications to Ground Conditions

Rock Hardness Classification Systems

Selecting the appropriate dth hammer bit requires thorough understanding of formation characteristics. Professional geologists use standardized rock hardness scales to classify different formations, from soft sedimentary rocks to extremely hard igneous formations. This classification guides bit selection by determining required button geometry and grade.

Modern drilling operations often employ advanced geological mapping techniques to anticipate formation changes and optimize bit selection. This proactive approach allows operators to select the most suitable dth hammer bit configuration for varying ground conditions.

Environmental and Operational Factors

Beyond rock hardness, environmental conditions significantly impact bit performance. Factors such as ground water presence, temperature variations, and abrasiveness of the formation all influence dth hammer bit selection. High-temperature applications may require specialized bit designs with enhanced heat dissipation features.

Operational parameters such as air pressure, rotation speed, and feed force must align with bit specifications for optimal performance. The wrong combination can lead to premature wear or catastrophic failure of the dth hammer bit.

Performance Optimization Strategies

Monitoring and Maintenance Protocols

Regular inspection of dth hammer bit wear patterns provides valuable insights for performance optimization. Establishing comprehensive monitoring protocols helps identify early signs of wear, allowing for timely maintenance or replacement decisions. This proactive approach minimizes unexpected downtime and extends bit life.

Documentation of drilling parameters and bit performance creates valuable historical data for future projects. This information helps refine bit selection criteria and optimize drilling parameters for specific applications.

Advanced Operating Techniques

Skilled operators understand the importance of proper breaking-in procedures for new dth hammer bits. Initial drilling parameters should be moderated to allow proper seating of buttons and development of sustainable wear patterns. Gradual increase in drilling parameters helps establish optimal performance levels.

Modern drilling rigs equipped with automated control systems can maintain ideal operating parameters throughout the bit's lifecycle. These systems adjust rotation speed and feed force based on real-time feedback, maximizing dth hammer bit efficiency and longevity.

Future Innovations in DTH Hammer Bit Technology

Smart Bit Development

The integration of sensors and monitoring technology directly into dth hammer bits represents the next frontier in drilling technology. These smart bits will provide real-time data on wear status, temperature, and impact forces, enabling predictive maintenance and performance optimization.

Manufacturers are exploring the use of advanced materials and surface treatments to further enhance bit durability and performance. Nano-engineered surfaces and composite materials show promise in extending service life while maintaining aggressive cutting action.

Sustainable Drilling Solutions

Environmental considerations are driving innovation in dth hammer bit design. New manufacturing processes focus on reducing carbon footprint while maintaining product quality. Recyclable materials and refurbishment programs help minimize environmental impact without compromising performance.

The development of eco-friendly drilling fluids and dust suppression systems complements advanced bit design, creating more sustainable drilling solutions for the future.

Frequently Asked Questions

How often should a DTH hammer bit be replaced?

The replacement interval for a dth hammer bit depends on several factors including rock hardness, drilling conditions, and operating parameters. Generally, bits should be inspected every 50-100 drilling hours, with replacement typically necessary after 200-600 hours of operation, depending on wear patterns and performance metrics.

What causes premature DTH hammer bit failure?

Common causes include incorrect operating parameters, mismatched bit selection for ground conditions, inadequate air pressure, and poor maintenance practices. Running bits beyond recommended wear limits or using excessive feed pressure can lead to catastrophic failure.

Can DTH hammer bits be refurbished?

While some components of dth hammer bits can be refurbished, such as regrinding worn buttons or replacing damaged ones, this process must be performed by qualified professionals using specialized equipment. The cost-effectiveness of refurbishment versus replacement depends on the extent of wear and bit design.