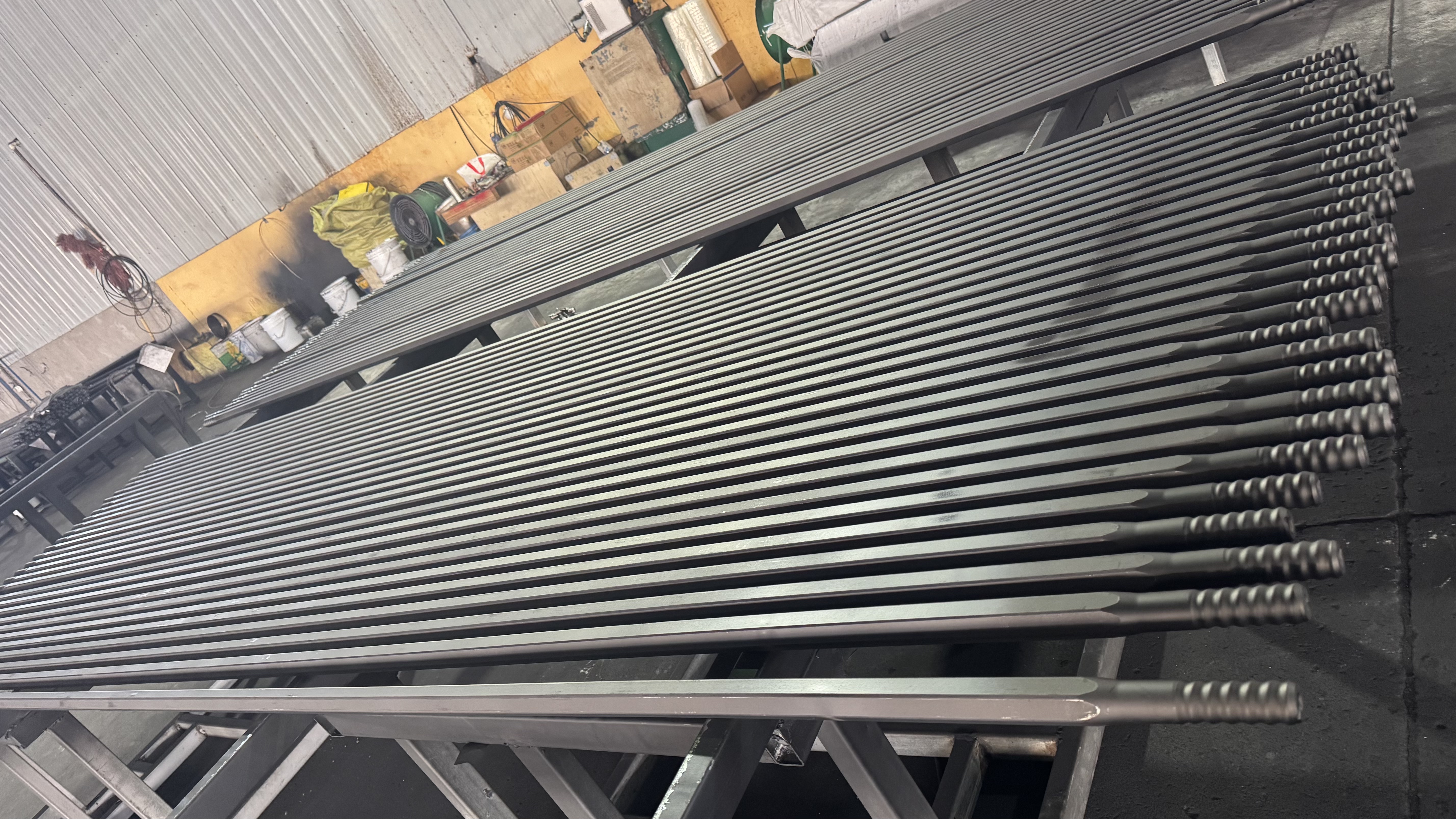

dth drill rod

The DTH drill rod is a crucial component in down-the-hole drilling operations, engineered for superior performance in challenging geological conditions. This essential drilling equipment combines robust construction with precision engineering to deliver exceptional drilling capabilities across various applications. Manufactured from high-grade steel alloys, DTH drill rods are designed to withstand extreme pressures and temperatures while maintaining structural integrity throughout extended drilling operations. The drill rod's innovative design features specialized threading systems that ensure secure connections and minimize the risk of thread wear during operation. These rods are specifically engineered to efficiently transfer both rotational force and percussion energy from the drill head to the hammer bit, maximizing drilling effectiveness. The rod's internal channel design facilitates optimal air flow, crucial for debris removal and hammer operation. Working in conjunction with DTH hammers, these drill rods excel in applications ranging from water well drilling and mining exploration to construction and quarrying operations. Their versatility makes them indispensable in both vertical and angled drilling projects, particularly in hard rock formations where traditional drilling methods may prove less effective.