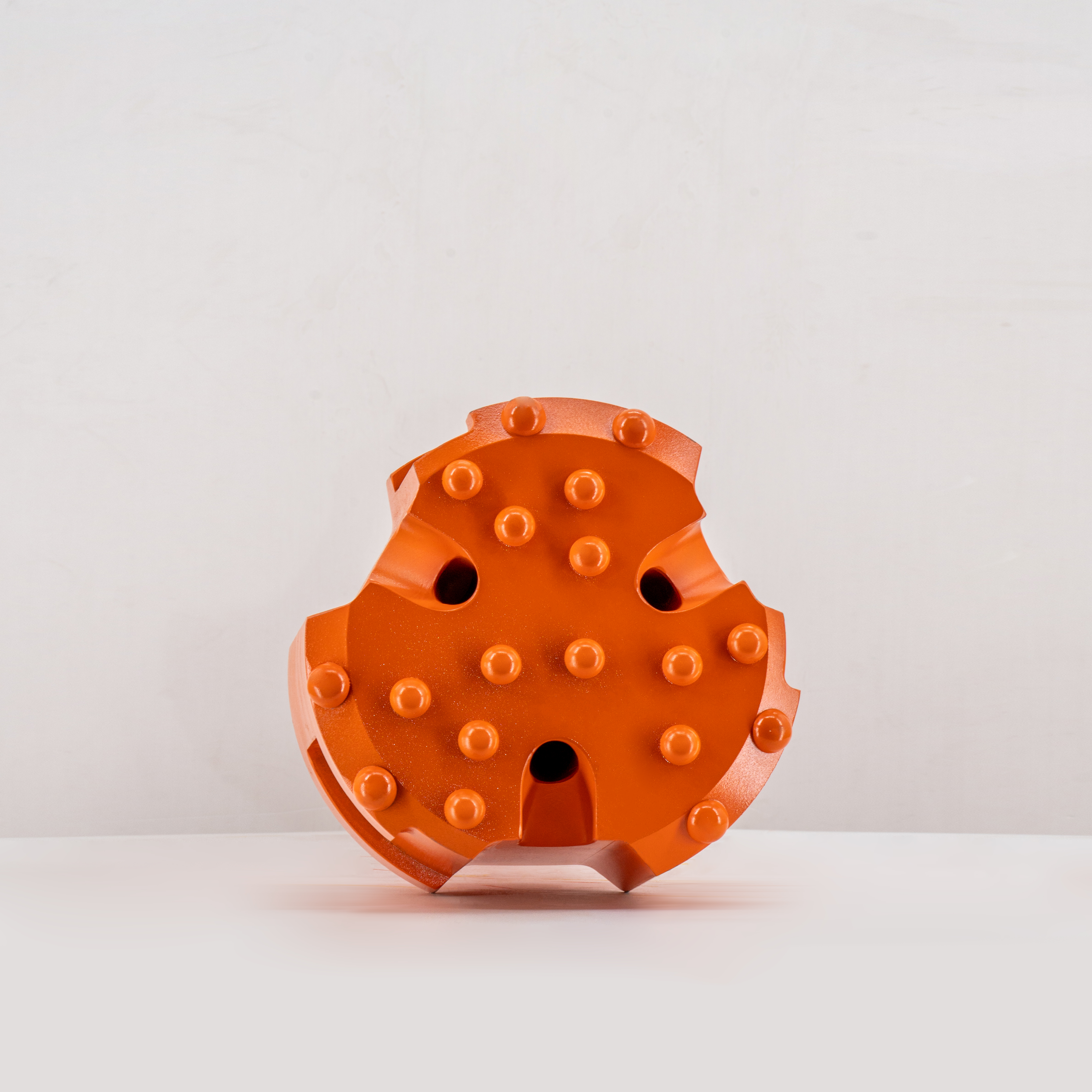

eccentric casing system

The eccentric casing system represents a groundbreaking advancement in industrial machinery design, offering unprecedented control over rotational movement and mechanical precision. This innovative system features a uniquely designed outer casing that deliberately offsets from the central axis, creating controlled asymmetrical motion patterns essential for various manufacturing processes. At its core, the system employs advanced bearing technology and precision-engineered components that work in harmony to convert regular rotational movement into carefully calculated eccentric patterns. The system's sophisticated design includes adjustable offset mechanisms that allow operators to fine-tune the degree of eccentricity based on specific application requirements. Essential components include hardened steel casings, precision bearings, and advanced sealing systems that ensure reliable operation even under demanding conditions. The eccentric casing system finds widespread applications across multiple industries, from automotive manufacturing to precision machining operations. It plays a crucial role in processes requiring controlled orbital motion, such as grinding, polishing, and specialized material forming operations. The system's versatility makes it particularly valuable in automated production lines where consistent, repeatable motion patterns are essential for quality control and efficiency.