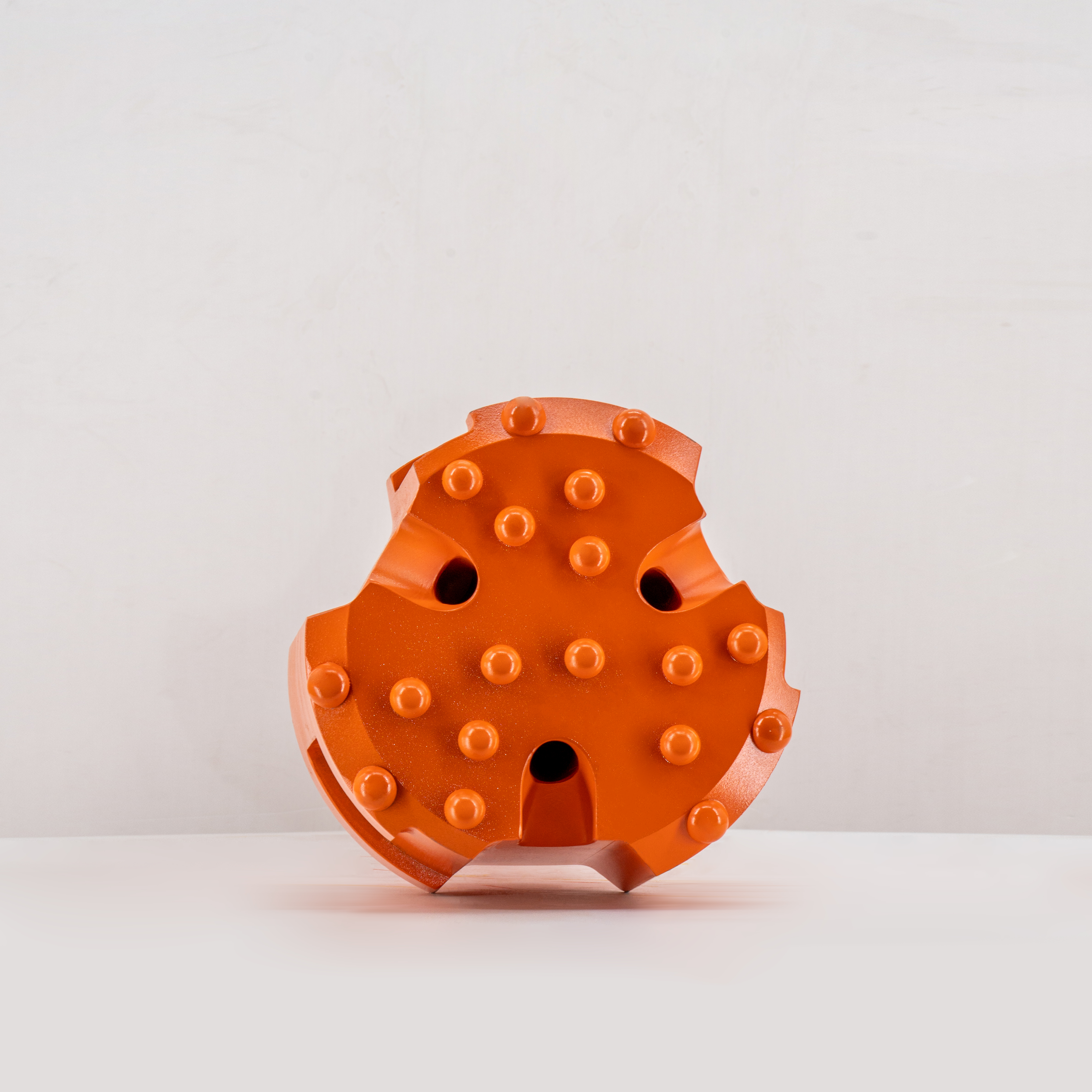

odex casing drilling

Odex casing drilling represents a sophisticated drilling technique specifically designed for challenging ground conditions where conventional drilling methods may prove ineffective. This innovative system combines a pilot bit with an eccentric reamer and casing tube, allowing simultaneous drilling and casing installation. The pilot bit leads the way, creating the initial hole, while the eccentric reamer enlarges the borehole to accommodate the casing. The system's unique design enables the casing to follow directly behind the drilling assembly, preventing borehole collapse in unstable ground conditions. The drilling process employs both rotation and percussion, with the casing advancing as the hole is drilled. Once the desired depth is reached, the drill string can be retrieved through the casing, leaving the casing firmly in place. This method proves particularly valuable in loose, unconsolidated soils, weathered rock, and areas with high groundwater tables. The technology incorporates advanced features such as specialized drill bits, robust casing tubes, and precise control systems to ensure accurate drilling and optimal performance. Applications span across various sectors, including geotechnical investigation, foundation work, ground anchoring, and water well construction.